The electrical control box, on the other hand, is what?

Users can operate and monitor a piece of equipment using a Control Box, a physical interface. A container housing the mechanism or device that regulates and controls anything (mainly electrical or radio waves) within a system.

An electrical control box is analogous to a human body: Our bodies have essential organs that regulate and monitor our environment. Control panels for mechanical processes are similar in that they contain crucial electrical equipment for controlling and electronically monitoring the operation. Industrial equipment and machinery require well-defined functions and systematic control to meet diverse process objectives. In manufacturing equipment, control boxes provide these roles.

STRUCTURE OF CONTROL PANELS

The construction of a control panel consists of an enclosure and numerous distinct types of electrical components. These components define and arrange the various functions carried out by the control panel. These components include:

Types of Control Boxes

What is a well pump control box and what does it do exactly? Continue reading to learn more.

Red and white floor marking tape is typically used in settings where clear visual communication is essential. The highly contrasting colors draw attention and provide clear cues. Common applications include

Brand Reputation

insulation tape price

Fire seal tape is widely used in numerous applications throughout the construction process. For instance, it is often applied in fire-rated walls and ceilings to seal penetrations created by electrical, plumbing, and HVAC installations. These penetrations can act as channels for smoke and heat, compromising the fire-resistance of a structure. By using fire seal tape, contractors can effectively minimize these vulnerabilities, thus enhancing the overall safety of the building.

Several grades of vinyl electrical tape are available — all of which differ in conformability, ease of unwinding, resistance of the adhesive to heat and cold, and loosening (flagging). While general-use vinyl tapes are appropriate for bundling, wire pulling, and other ancillary tasks, premium-grade vinyl tape is the best choice for permanent insulation work as it handles the broadest range of environmental factors and functions, such as cold weather.

Butyl rubber based tapes have excellent UV and aging resistance but lower mechanical strength. These tapes are used in foam tape applications and construction and plumbing applications such as pipe joints.

This is especially important for homes located in areas with high levels of precipitation or near bodies of water This is especially important for homes located in areas with high levels of precipitation or near bodies of water

This is especially important for homes located in areas with high levels of precipitation or near bodies of water This is especially important for homes located in areas with high levels of precipitation or near bodies of water waterproof door seal strip.

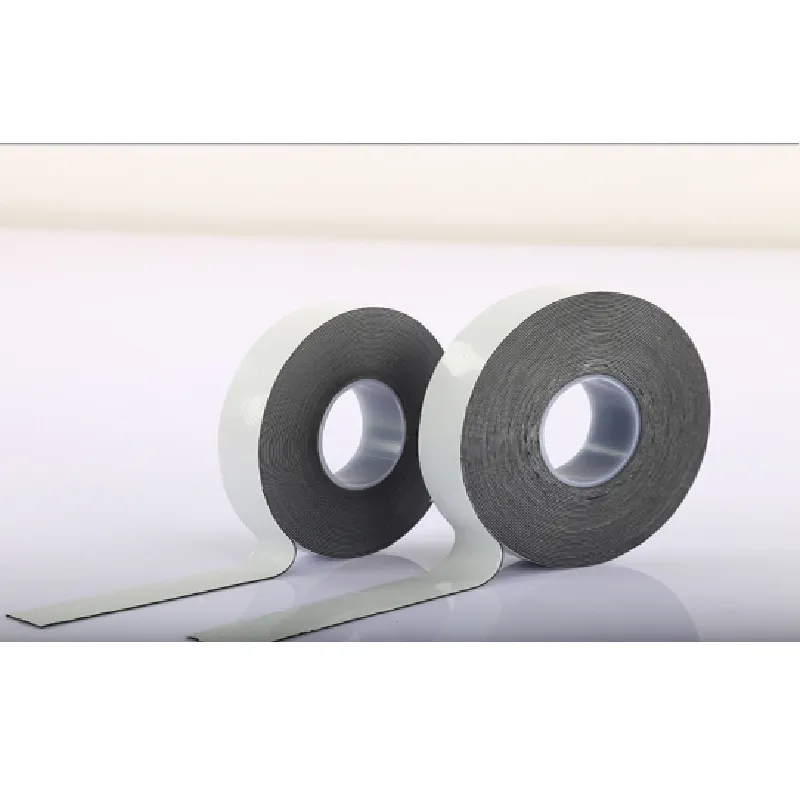

waterproof door seal strip. To use the tape, simply stretch it around the material you are trying to repair. As you wrap the tape in a circular motion, it begins to seal and “fuse” itself to the material. The most common forms of self-fusing / self-amalgamating tapes are made of silicone rubber (though other types also exist). They are designed to create a strong, seamless, rubbery, waterproof, and electrically insulating layer.

It can withstand heavy foot traffic, harsh chemicals, and extreme temperatures, making it an ideal choice for high-traffic areas It can withstand heavy foot traffic, harsh chemicals, and extreme temperatures, making it an ideal choice for high-traffic areas

It can withstand heavy foot traffic, harsh chemicals, and extreme temperatures, making it an ideal choice for high-traffic areas It can withstand heavy foot traffic, harsh chemicals, and extreme temperatures, making it an ideal choice for high-traffic areas