mineral fiber planks

Links

-

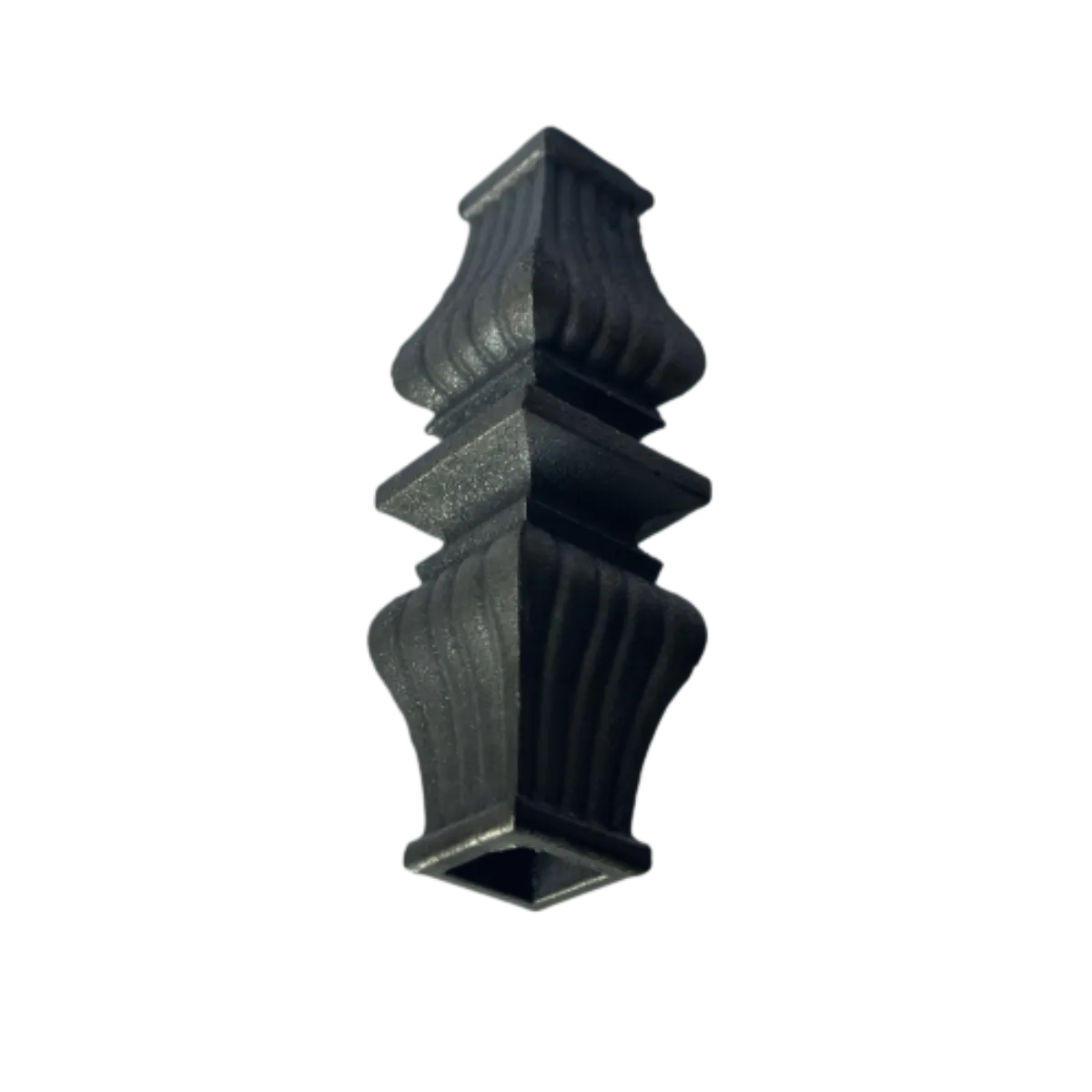

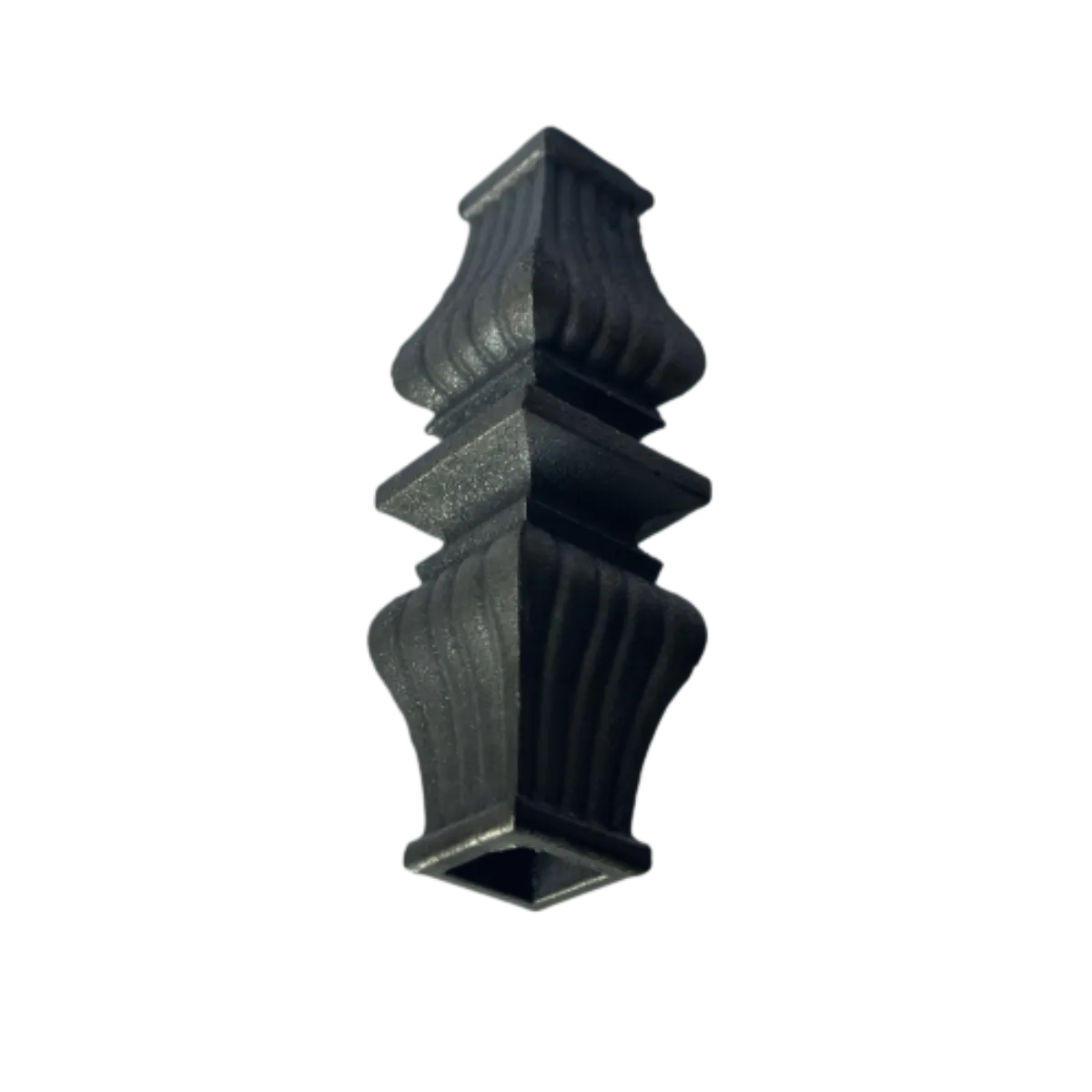

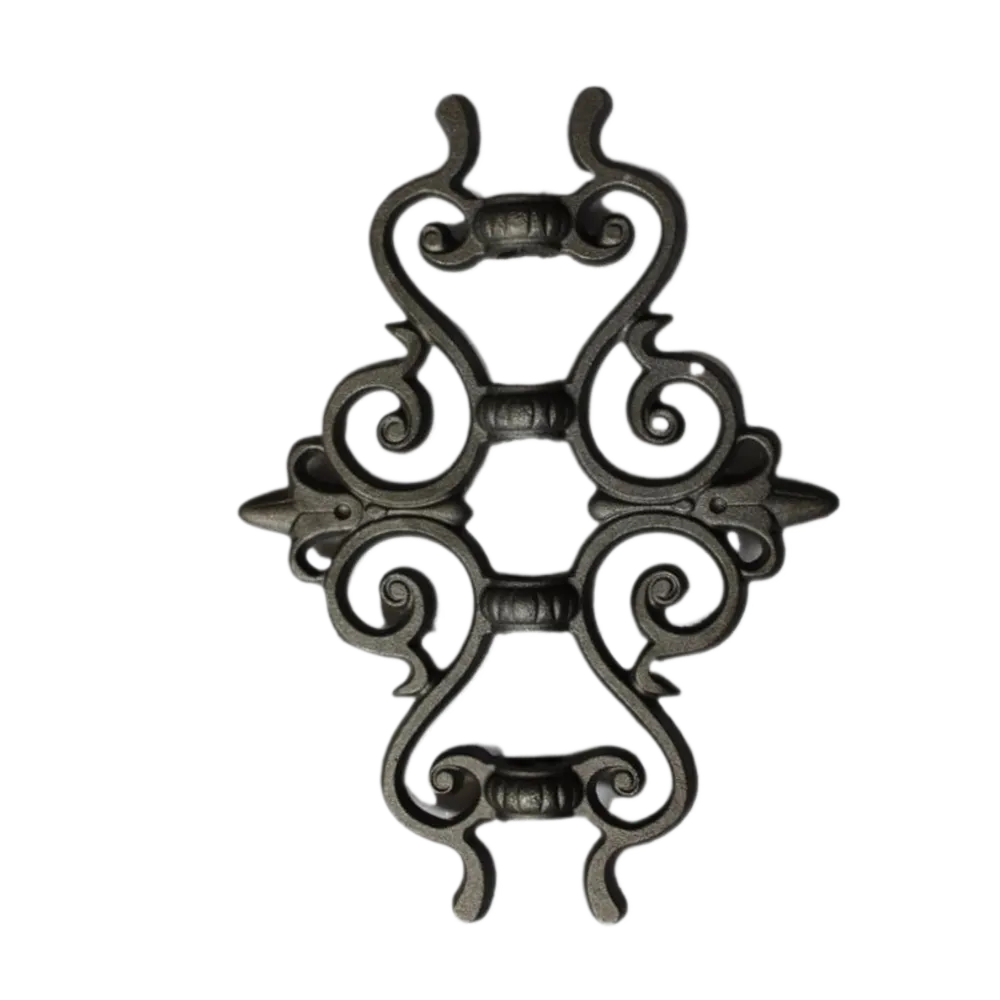

Wrought iron fence ornaments are more than just decorative elements; they are timeless pieces that add character and elegance to any property. With their rich history, durability, and aesthetic versatility, these ornaments can elevate the allure of traditional and modern homes alike. By incorporating wrought iron into your fencing or landscaping, you not only enhance the visual appeal but also invest in a piece of art that will last for generations. Whether you're drawn to intricate designs or minimalist styles, there’s a wrought iron ornament to suit every taste, ensuring your fence is a true reflection of your unique personality.

-

- Modern look.

- One of the main benefits of a metal cash box with a lock is its durability. Made from high-quality steel or aluminum, these boxes are designed to withstand daily wear and tear, ensuring that your money is kept safe and secure at all times. The lock mechanism adds an extra layer of security, making it difficult for unauthorized individuals to access your cash.

-

In conclusion, wrought iron gate ornaments embody a harmonious blend of style, durability, and tradition. Their presence enhances the beauty of architectural designs while providing functional security and longevity. As trends in home design continue to evolve, wrought iron remains a timeless option that appeals to those who appreciate the artistry of craftsmanship and the enduring allure of metalwork. Whether in a historic estate or a modern home, wrought iron gate ornaments will always stand as a testament to the elegance of form and function.

Once detached, dispose of the old wheels responsibly Once detached, dispose of the old wheels responsibly

Once detached, dispose of the old wheels responsibly Once detached, dispose of the old wheels responsibly wheel replacement for sliding screen door.

wheel replacement for sliding screen door.

Cons

Introduction

Interlocking

Aluminium Extrusion Profiles and Their Applications in the Windows and Doors Segment

One of the distinctive features of Slatwall is the gaps that have been made as a result of the paneling installation process. These gaps or “slots,” are where hangers and hooks are attached. Retailers can add as many hangers to each slot layer as they see fit because of the high level of adjustability.

metal gate latch. Pool gate latches are essential for keeping children and pets safe around swimming pools.

The process of welding metal leaves requires a high level of precision and skill. Due to their thinness, they can easily distort or burn through under intense heat, making the welding process a delicate balancing act between power and control. TIG (Tungsten Inert Gas) welding or MIG (Metal Inert Gas) welding, with their ability to provide precise control over the heat source, are commonly employed for such tasks. The use of protective gases helps to prevent oxidation and maintain the integrity of the metal leaves during the process.

metal leaves for welding

screen slider wheels. This can include cleaning the wheels and tracks regularly to remove any dirt or debris that could cause the wheels to become clogged or sticky. Lubricating the wheels with a silicone-based lubricant can also help to keep them moving smoothly and prevent them from wearing out prematurely.