hard ceiling access panel

-

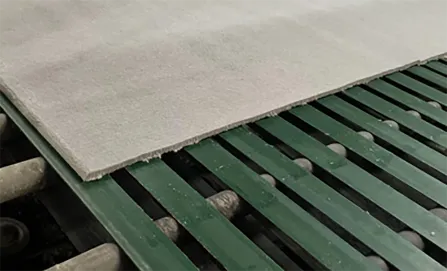

Fiberglass ceiling tiles are renowned for their durability and versatility. Made from fine glass fibers, these tiles are lightweight yet sturdy, making them suitable for a wide range of applications. Their composition allows for easy cutting and installation, seamlessly integrating them into various ceiling systems. Fiberglass ceiling tiles are available in a plethora of designs, textures, and patterns, offering endless possibilities for creating captivating ceilings.

...

-

If you’re using a pre-made access panel, follow the manufacturer's instructions. If you're creating your own frame, cut wooden supports to fit inside the opening, securing the frame with drywall screws to the existing ceiling joists. This will provide a sturdy structure for the panel.

...

Links

-

Additionally, propeller pumps are extensively used in industrial applications, such as in cooling systems for power plants and manufacturing facilities. They circulate water or other cooling fluids to regulate temperature, thus preventing overheating and ensuring operational efficiency. The design of propeller pumps allows them to operate continuously, which is ideal for industrial settings where downtime can lead to significant losses.

-

- Review the performance curves for the selected pump models to ensure they meet your flow rate and head requirements.

-

-

5. Shaft and Bearing Assembly

-

Enhancing Durability with High Pressure Vertical Pumps

-

b. Selection Software:

-

Understanding Slurry Pump Wet End Parts A Comprehensive Overview

-

-

-

- Select the impeller design that best handles the slurry's characteristics (e.g., closed impellers for abrasive slurries, open impellers for large particles).

-

-

- Packing Seals: Use a packing material to create a seal around the shaft.

-

Enhancing Productivity with AH Slurry Pump Parts

-

Horizontal inline centrifugal pumps are among the most versatile pumps available, widely used across industries for their reliability and ease of maintenance. Unlike vertical pumps, these pumps are installed horizontally, which typically makes them easier to service and maintain. The horizontal design allows for more straightforward access to the pump’s internal components, which can be a significant advantage in applications where regular maintenance is required. Additionally, horizontal inline centrifugal pumps are capable of handling a wide range of fluid viscosities and flow rates, making them suitable for various industrial processes. Their versatility and robust construction make them a popular choice for many fluid handling applications.

- content

-

-

One of the primary advantages of purchasing wholesale slurry pumps is cost efficiency. When companies buy in bulk, they can take advantage of reduced prices, resulting in significant savings. This is especially beneficial for large-scale projects where multiple pumps are required. In addition, wholesale suppliers typically offer a wide range of models and specifications, allowing businesses to choose the most appropriate pump according to their unique needs. This capability ensures that operations can run smoothly and efficiently without significant downtime caused by equipment failure.

-

Monitoring Wet Parts for Optimal Pump Performance

-

Wet parts in a pump, including the impeller, casing, and liners, are continuously exposed to the fluid being pumped, making them prone to wear. Monitoring the condition of these wet parts is crucial for maintaining pump performance. Regular checks and the use of wear indicators can help you determine when a pump wet end replacement is necessary. By establishing a monitoring routine and setting clear wear thresholds, you can replace these components before they fail, thus avoiding unscheduled downtime and extending the overall lifespan of the pump.

-

Wear Factors: These components experience wear from the slurry and need to be checked regularly.

-

a. Slurry Characteristics:

-

- Choose materials that can withstand the slurry's abrasiveness and corrosiveness. Common materials include high-chrome alloys, stainless steel, and rubber linings.

-

- Check the power requirements and ensure compatibility with your available power supply.

-

-

- Concentration: Measure the percentage of solids by weight or volume in the slurry.

-

Wear Factors: Liners experience wear from the continuous contact with the slurry.

-

-

In line vertical pumps are specifically designed to save space while delivering efficient performance. These pumps are installed directly in the pipeline, with the motor positioned vertically, reducing the overall footprint of the pump system. This design is particularly beneficial in applications where space is limited, but high performance is still required. In line vertical pumps are commonly used in HVAC systems, water treatment plants, and other industries where compact, efficient pumping solutions are needed. The vertical orientation of these pumps also allows for easier alignment and installation, which can reduce the time and cost associated with setting up a pump system.

-

- Choose materials that can withstand the slurry's abrasiveness and corrosiveness. Common materials include high-chrome alloys, stainless steel, and rubber linings.

-

Function: The impeller is responsible for moving the slurry through the pump by converting mechanical energy into kinetic energy.

-

Assessing Head and Pressure in Centrifugal Slurry Pumps

-

2. Use a Selection Chart or Software

-

Understanding Sewage Pump Impellers A Key Component in Waste Management

-

The Role of Casting Slurry Pump Parts in Wear Management

-

In conclusion, sewage pump impellers are integral to wastewater management systems. By understanding their types, materials, and maintenance, operators can make informed decisions that enhance the efficiency and reliability of sewage pumping operations, ultimately contributing to effective waste management solutions.

-

In conclusion, wholesale slurry pumps play an essential role in various industrial applications by providing the necessary tools for effective slurry management. Their durability, cost efficiency, and technological advancements make them the preferred choice for businesses aiming to enhance productivity and operational efficiency. As industries continue to evolve, the demand for reliable and efficient slurry pumps will only increase, emphasizing the importance of these robust machines in modern manufacturing and resource processing sectors. Investing in quality wholesale slurry pumps is not just a purchase; it is a strategic move toward achieving long-term operational success.

-

-

The centrifugal slurry pump design plays a significant role in the effective transportation of slurry in mining operations. The design ensures that the pump can handle high-density materials without compromising performance. This is particularly important in mining, where the slurry often contains heavy and abrasive particles that can wear down pump components. The robust construction and optimized design of horizontal slurry pumps allow them to move large volumes of slurry over long distances, ensuring that materials are efficiently transported from extraction sites to processing facilities. By selecting the appropriate centrifugal pump for slurry, mining operations can maintain consistent material flow, reduce downtime, and enhance overall productivity.

-

5. Seals

-

Wear Factors: Continuous contact with the slurry and seals can cause wear on the shaft sleeves.

-

- Most slurry pump manufacturers provide selection charts that correlate slurry characteristics and operating conditions with suitable pump models.

-

Propeller pumps are a crucial element in the field of fluid dynamics, primarily utilized for their efficiency in moving large volumes of fluids. These pumps operate on a simple principle they use a rotating propeller to impart energy to the liquid, creating a flow that can be directed to various applications. This article explores the various uses and advantages of propeller pumps.

-

Evaluating the performance and efficiency of horizontal centrifugal slurry pumps involves a comprehensive approach to testing key metrics such as flow rate, head, and efficiency. These tests are essential for ensuring that the centrifugal slurry pump operates according to expected standards and can handle the demands of slurry transport using centrifugal pumps. Regular monitoring and maintenance of AH Slurry Pump parts further contribute to sustaining the pump’s performance, reducing operational costs, and extending the pump’s service life. By focusing on these critical areas, manufacturers and operators can optimize the performance and reliability of horizontal centrifugal slurry pumps, ensuring their continued success in industrial applications.

-

Wear plates are installed within the pump casing to protect the surfaces from the erosive wear caused by the particles in the slurry. These plates can be easily replaced when worn, allowing for maintenance without needing to replace the entire pump. Some wear plates are designed to be adjustable to optimize the pump's performance by fine-tuning the clearance around the impeller.

-

-

a. Manufacturer’s Support:

-

Function: The expeller and expeller rings work together to reduce the pressure and minimize leakage from the pump.

-

-

Conclusion

-

- Angular Contact Ball Bearings Product Guide and Specifications Overview

- 28580 bearing

- weizi bearing bearing ball deep groove

- Roulements à contact angulaire - Performance et Précision

- weizi bearing bearing pressing machine

- weizi bearing cylindrical roller bearing supplier

- weizi bearing nj 206 bearing

- weizi bearing 23244 bearing

- Similar title to 4T L44649 Bearing can be Replacement Bearing for 4T L44649, High Quality and Durable

- Design and Applications of Single Thrust Ball Bearings in Machinery Systems