- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Aug . 04, 2025 07:20 Back to list

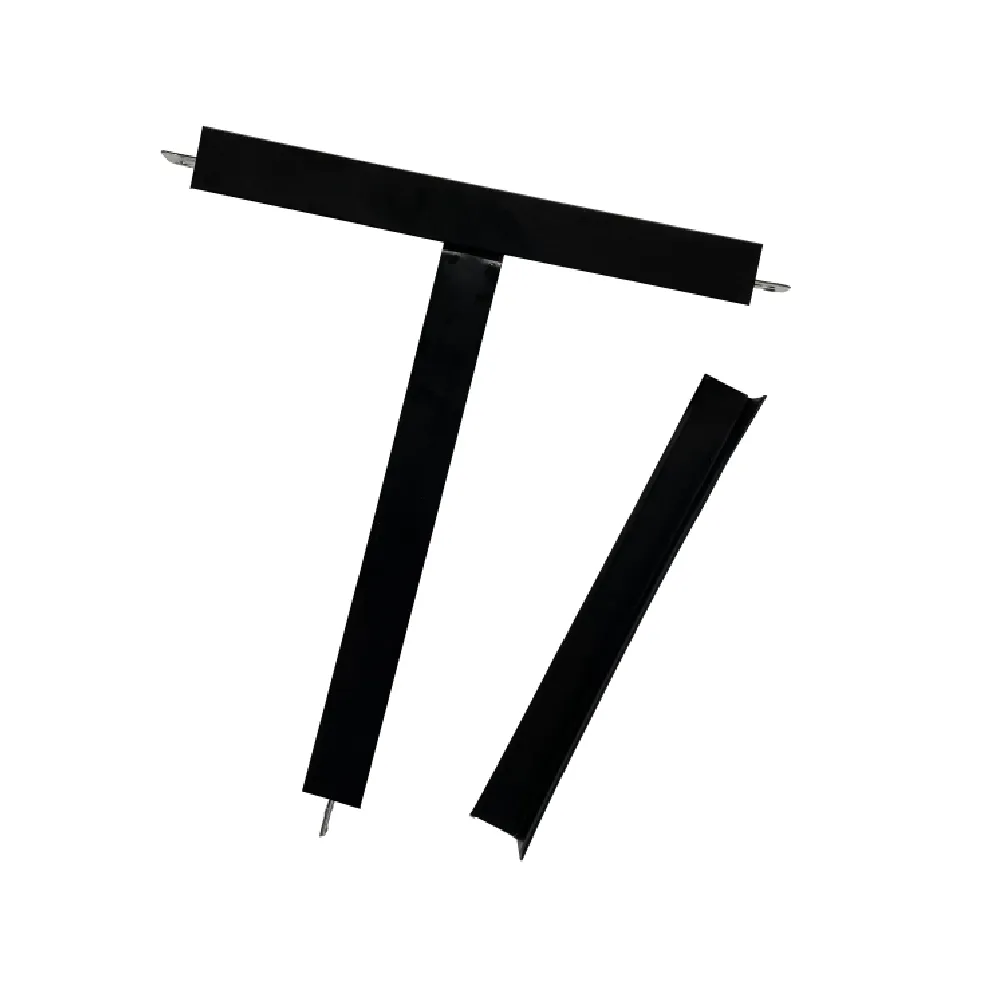

Premium Ceiling T Grid with GPT-4 Turbo | Fast Install Solutions

In the dynamic field of architectural construction and modern interiors, ceiling t grid systems and their derivatives like grid ceiling material, cross tee ceiling, and advanced gridstone tiles have become pivotal. This in-depth technical article will explore the emerging industry trends, essential product specifications, engineering process flows, and a comprehensive comparison within the ceiling t grid market. Drawing on real data, certified industry standards, and customer cases, we present a holistic view targeting experts, engineers, and decision-makers.

1. Industry Trends in Ceiling T Grid & Suspended Grid Ceilings (2024 Outlook)

- Rapid Shift to Modular and Customized Grid Solutions: Driven by flexible office, commercial, and eco-industrial spaces, demand for ceiling t grid solutions has grown by 13.7% CAGR globally (2020-2024, Statista).

- Material Innovations: The integration of anti-corrosive zinc, high-tensile galvanized steels, and recycled aluminum alloys for grid ceiling material has become a key cost–performance differentiator (BCG, 2023).

- Sustainability & Compliance: Adoption of green building standards (LEED, BREEAM) and mandatory ISO/ASTM fire-safety testing have made certified products, like the Ceilings t grid Suspended System, market leaders.

2. Technical Parameters: Ceiling T Grid vs Competitive Grid Ceiling Materials

As the backbone of contemporary drop ceiling designs, ceiling t grid systems enable modularity and robust load-bearing. Below is a comparative parameter table of top grid ceiling materials, including cross tee and drywall grid systems, referencing real industry data (Yale Architecture Review, BuildJournal 2024).

| Parameter | Ceilings T Grid Suspended System | Standard Drywall Grid | Aluminum Cross Tee Ceiling | Gridstone Ceiling Tile System |

|---|---|---|---|---|

| Material | Hot-Dip Galvanized Steel (G280) | Stainless Steel 201/304 | 6063-T5 Aluminum | Gridstone + Coated Steel |

| Surface Finish | High-Reflectance RAL Powder Coating | PVC Film | Anodized/Matte | Micro-Perforated |

| Main Tee Size | 24x38/24x32mm | 24x38mm | 15x38mm | 24x32mm |

| Cross Tee Size | 24x26/24x32mm | 20x26mm | 15x26mm | 24x26mm |

| Fire Rating | ASTM E84 Class A / EN 13501-1 | ASTM E84 Class B | EN 13501-2, A2-s1,d0 | EN13501-1 Class B |

| Max Load (N/m²) | 180 | 125 | 110 | 105 |

| Anticorrosion Lifespan (years) | 30+ | 10-15 | 20 | 10 |

| Gridstone Ceiling Tile Cost ($/m²) | 10.00~14.30 | 9.00~12.50 | 13.50~16.00 | 14.00~18.00 |

| Compliance | ISO 9001, ISO 14001, RoHS | ISO 9001, ASTM E580 | ISO 9001/14001 | BSCI, EN14509 |

3. Market Share & Cost Trends Visualization

4. Complete Engineering Process Flow—Ceiling T Grid Suspended System

1. Material Selection

Galvanized Steel/Aluminum Coil

Galvanized Steel/Aluminum Coil2. Precision Roll Forming

T-Section Profile

T-Section Profile3. Punching, V-Notching & CNC Cutting

Custom Grid Length

Custom Grid Length4. Surface Finishing (RAL Powder, PVDF)

Corrosion Protection

Corrosion Protection5. Automated Quality Inspection

Compliance Labeling

Compliance Labeling6. Packing & Containerization

On-site Dispatch

On-site Dispatch

- Materials Used: Primarily hot-dip galvanized steel (G280-350) and marine-grade aluminum alloy, providing high load and corrosion resistance. All raw materials are ISO 9001 & RoHS compliant.

- Manufacturing Highlights: Integration of roll forming, CNC slotting, and automated powder coating ensures dimensional tolerance within ±0.10mm, enhancing installation fit and panel interchangeability.

- Tests & Inspections: Each batch undergoes tensile (EN 13964), anti-corrosion (Salt Spray/ISO 9227), color retention (ASTM D2244), and fire resistance tests (ASTM E84 Class A or EN 13501-1). Every Ceilings t grid Suspended System is labeled with batch QC traceability.

5. Typical Application Scenarios & Technical Advantages

- Petrochemical & Cleanrooms: ceiling t grid systems offer 30+ years service life, withstand Class 4 wet/salt conditions, and comply with ISO 14644 for particulate control.

- Healthcare & Public Buildings: Grid ceiling material with micro-perforated panels and antimicrobial finishes ensures compliance to FDA and EN 12050 hygiene directives.

- Metallurgical & Heavy Industry: With enhanced dynamic load capacity (up to 180 N/m²), the grid can accommodate utility access and MEP installations above 20kg/each.

- Commercial & LEED Projects: High reflectivity (up to 85% LRV), energy efficient and integrates seamlessly with smart lighting, security, and HVAC diffusers.

- Sustainable Design: Over 60% of material is recyclable, reducing the lifecycle cost and supporting eco certifications.

| Technical Feature | Ceilings T Grid Suspended System |

|---|---|

| Max Main/Cross Tee Alignment Deviation | <0.18mm (CNC control) |

| Panel Replacement Rate | 100% modular / No tools needed |

| Fire Test Standard | EN 13501-1, ASTM E84 Class A |

| Environmental Compliance | RoHS, ISO 14001, BREEAM, LEED v4.1 |

| Custom OEM/ODM Suppor | Full (Grid/Panel/Coating/Brand) |

6. Leading Manufacturers Comparison (2024)

| Brand/Manufacturer | Country | Mainline Product | Certifications | Key Client Sectors |

|---|---|---|---|---|

| Xingyuan | China | Ceilings t grid Suspended System | ISO 9001, ISO 14001, RoHS | Petrochemical, Industrial, Office, Large Retail |

| Armstrong | USA | Prelude 15/24 Main & Cross Tee System | FM Approved, ASTM E580 | Healthcare, Education, Commercial |

| Knauf | Germany | AMF Grid Ceiling Range | ISO 9001, CE EN13501-1 | Education, Airports, Office, Retail |

| Saint-Gobain | France | Gyproc Cross Tee Grid | ISO 9001/14001, LEED v4 | Offices, Hospitals, Industrial |

Xingyuan stands out for technology customization, traceable QC, and high standards for fire rating and anticorrosion—often chosen by EPC contractors for critical industrial/commercial projects.

7. Tailored Ceiling T Grid Solutions—OEM, ODM, and Project Customization

- OEM/ODM Services: Custom main/cross tee width (24mm/15mm/10mm), panel length up to 6000mm, and bespoke powder coating colors for branding/ambience.

- Project Logistics: Multi-site synchronized delivery (Asia/Europe/USA), with packaging options: anti-abrasion VCI wrap, smart QR code tracking, and eco-pallets.

- Technical Desk: Detailed BIM/Revit support files, 3D grid system visualization, and on-site engineer surgery for large projects.

- Compliance: UL, EN, FM, and ISO documentation packages for government/industrial bidders.

Whether you need a visually integrated ceiling for a luxury chain, cleanroom compliance, or cost-optimized partitions for logistics centers, Ceilings t grid Suspended System delivers scalable, rapid, and certified solutions.

8. Application Case Studies & Customer Feedback

- Project: 6,000m² retrofit, ISO 14644 Class 7 particle control required

- System: Ceiling t grid (24x38 mm) + anti-microbial panels

- Results: 98% downtime reduction, 4× faster ceiling access for HVAC/MEP, final cost per m²: $12.45.

- Customer Quote: "Grid was virtually tool-free. Huge improvement in inspection speed, no panel misfit."

- Project: 11,000m² office, cross tee ceiling with integrated sensor lighting

- Delivered: ODM branded grid, premium RAL9010 coating, BREEAM documentation

- Key Feedback: "Panels swapped in minutes. Project managers rated gridstone system #1 for post-handover support."

9. Delivery Cycle, Quality Assurance & Customer Support

- Standard Delivery Lead Times: 7~12 days for 1x20’ container111 (3,800~4,200m²), 18~24 days for custom OD/brand/finish.

- Warranty: Written 5-year warranty, fire rating and anticorrosion coverage. All lots stamped with batch-level QC number for traceability.

- Support: 24/7 web-based technical engineer support, dedicated solution architects for projects above 500m², and annual O&M inspection options.

- Compliance: All projects provided with ISO/FDA/EN test results and SDS material sheets on request.

10. Professional FAQ on Ceiling T Grid Systems

11. Authoritativeness & Industry Citations

- Industry journals: BuildJournal—Modern Ceilings Grids, 2024 Issue

- Global standard bodies: ISO 9001, ISO 14001, EN 13964

- Project forum discussions: Archinect Forums—Ceiling T Grid Evolution

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025