- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

dets. . 20, 2024 14:06 Back to list

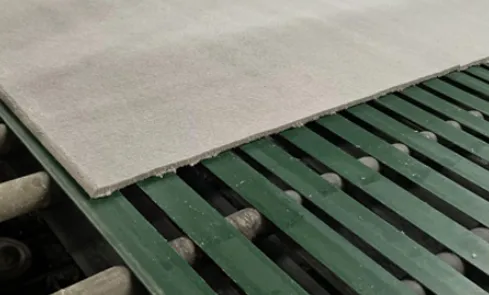

mineral fiber planks

The Benefits and Applications of Mineral Fiber Planks

Mineral fiber planks, often referred to as mineral wool or rock wool boards, have emerged as a popular choice in various industries due to their versatile properties and eco-friendly credentials. This article explores the benefits of mineral fiber planks, their applications, and why they are a superior choice in building materials.

Understanding Mineral Fiber Planks

Mineral fiber planks are primarily composed of natural, inorganic materials, making them a sustainable option for construction and insulation. They are produced through a process that involves the melting of rocks or minerals at high temperatures, followed by spinning the melted materials into fibers. These fibers are then compressed into planks or boards. The resulting material boasts remarkable thermal insulation, sound absorption, and fire-resistant properties, making them ideal for a wide range of applications.

Thermal Insulation

One of the standout features of mineral fiber planks is their excellent thermal insulation capabilities. They are capable of maintaining optimal temperatures in buildings, which can significantly reduce energy costs. This thermal efficiency is particularly beneficial in regions with extreme weather conditions, as it helps in keeping interiors warm during winter and cool during summer. The high R-value of mineral fiber also means that less energy is required for heating and cooling, leading to lower environmental impact and sustainability.

Acoustic Performance

In addition to thermal insulation, mineral fiber planks are renowned for their sound-dampening properties

. Their dense fiber structure helps to absorb sound waves, making them an ideal choice for applications that require noise reduction, such as offices, schools, and concert halls. Incorporating these planks into walls and ceilings not only enhances the acoustic comfort of a space but also creates a more conducive environment for communication and productivity.mineral fiber planks

Fire Resistance

Safety is a paramount concern in construction, and mineral fiber planks excel in this regard due to their inherent fire-resistant qualities. These planks do not combust and can withstand high temperatures, thus providing essential fire protection in buildings. They can act as a barrier, preventing the spread of flames and smoke, and are often used in fire-rated wall systems and ceilings. This characteristic not only enhances the safety of occupants but also ensures compliance with building safety codes and regulations.

Environmental Considerations

As sustainability continues to dominate conversations in construction, mineral fiber planks offer an eco-friendly alternative to traditional materials. They are often made from recycled content and are recyclable themselves, minimizing waste. Moreover, their production process consumes less energy compared to the manufacturing of plastic-based insulators. By choosing mineral fiber planks, builders contribute to a healthier planet while still obtaining high-performance building materials.

Applications in the Building Industry

Mineral fiber planks are widely employed in various sectors, including commercial, industrial, and residential buildings. They are commonly used as ceiling tiles, thermal insulation for walls, and in HVAC systems to improve acoustic comfort. Their adaptability allows them to be utilized in a range of architectural designs, making them suitable for both modern and traditional buildings.

Conclusion

Mineral fiber planks stand out as a superior choice in building materials, providing exceptional thermal insulation, sound absorption, and fire resistance while championing sustainability. Their numerous applications across different industries highlight their versatility and effectiveness. By leveraging the benefits of mineral fiber planks, builders and architects can create safe, energy-efficient, and healthy living and working environments. With the growing emphasis on environmental responsibility, mineral fiber planks are poised to play a crucial role in the future of sustainable construction.

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025