- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Aug . 09, 2025 04:00 Back to list

High-Quality Ceiling T Grid Systems & Materials

In the vast landscape of modern construction and interior design, the humble ceiling plays a far more critical role than mere overhead cover. It serves as a canvas for aesthetic expression, a conduit for essential utilities, and a crucial component in acoustic and thermal management. At the heart of many sophisticated ceiling systems lies the ceiling t grid, a foundational element that defines structure, facilitates installation, and ensures the long-term performance of suspended ceilings. This comprehensive guide delves into the intricate world of suspended T-grid systems, focusing on the Ceilings T Grid Suspended System, exploring its technical prowess, diverse applications, and the rigorous standards that underpin its quality and reliability.

Navigating the Evolving Landscape of Suspended Ceilings: Trends and Innovations

The global demand for efficient, adaptable, and aesthetically pleasing interior spaces continues to drive innovation in the suspended ceiling market. Industry reports indicate a robust growth trajectory, with the global suspended ceiling market size valued at approximately USD 20 billion in 2023 and projected to reach over USD 30 billion by 2030, demonstrating a Compound Annual Growth Rate (CAGR) exceeding 6%. This growth is fueled by several key trends:

- Sustainability and Green Building Initiatives: Increasing emphasis on environmentally friendly materials, energy efficiency, and indoor air quality (IAQ) is driving demand for T-grid systems made from recycled content and those that facilitate better thermal insulation and air circulation.

- Modularity and Adaptability: Modern commercial and institutional spaces require flexibility. Ceiling t grid systems, with their inherent modularity, allow for easy integration of lighting, HVAC, and communication systems, as well as simple reconfigurations of office layouts.

- Aesthetics and Design Versatility: Beyond functionality, architects and designers are leveraging T-grid systems to create visually appealing spaces. This includes exploring various finishes, grid patterns, and integrating them with diverse ceiling tile materials like mineral fiber, gypsum, metal, and wood.

- Enhanced Performance: There's a growing need for ceilings that offer superior acoustic performance, fire resistance, moisture resistance, and even anti-microbial properties, particularly in healthcare and educational facilities.

- Cost-Efficiency and Installation Speed: The ease and speed of installation offered by pre-engineered ceiling t grid components significantly reduce labor costs and project timelines, making them a preferred choice for large-scale commercial constructions. This directly impacts the overall drywall ceiling grid price and project budget.

Understanding the Ceilings T Grid Suspended System: Technical Parameters and Specifications

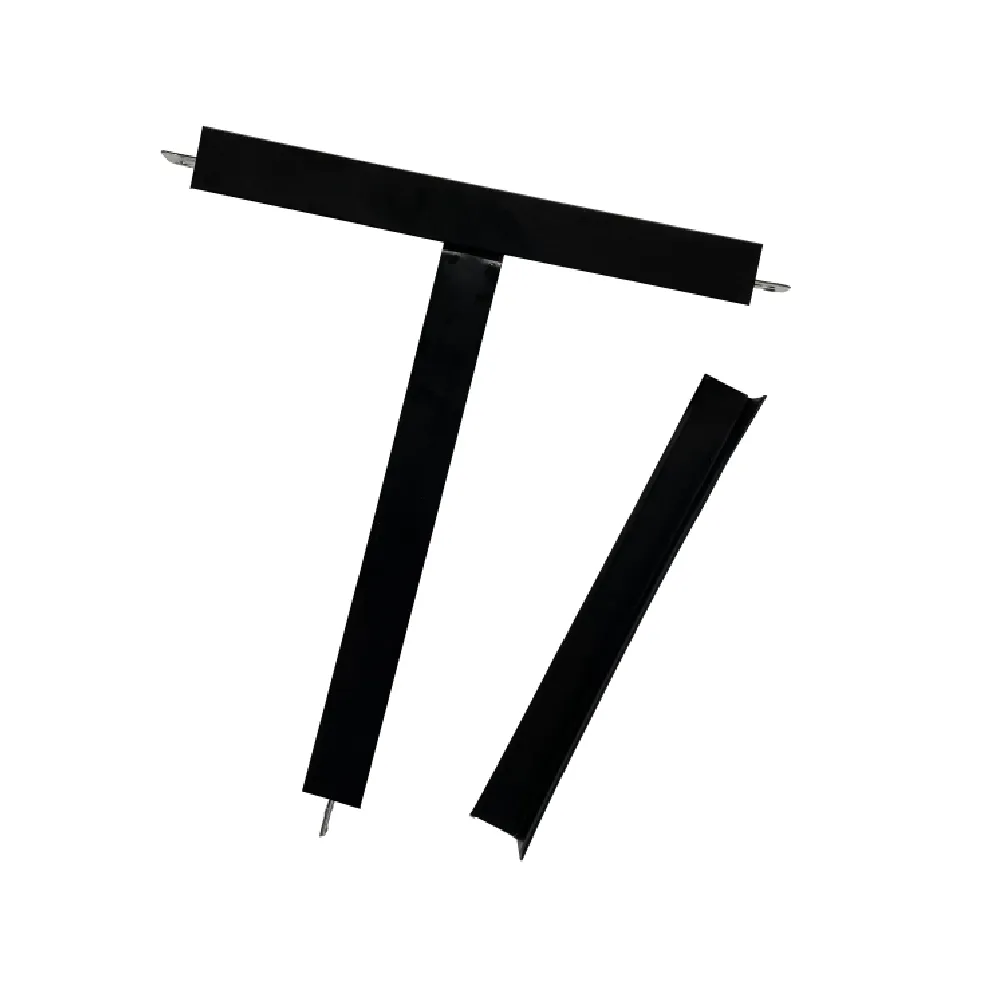

The Ceilings T Grid Suspended System is engineered for optimal performance and durability. It typically comprises three primary components: the main tee, the cross tee, and the wall angle, all designed to interlock and form a robust framework for ceiling panels. The precision in manufacturing these components is paramount to ensuring structural integrity and ease of installation.

Key Technical Specifications of a Standard T-Grid System:

| Parameter | Standard Specification (Typical) | Xingyuan Ceilings System Data | Benefit/Application |

|---|---|---|---|

| Material | Galvanized Steel (Hot-dipped) | Premium Hot-Dip Galvanized Steel (G60/G90 Equivalent) | Superior corrosion resistance, extended lifespan, suitability for diverse environments. |

| Main Tee Length | 3600 mm (12 ft) or 3660 mm (12 ft 6 in) | 3660 mm (12 ft) | Standard span, reduced joints for structural integrity and faster installation. |

| Main Tee Height (Web) | 24 mm - 38 mm (0.94 - 1.5 in) | 38 mm (1.5 in) | Higher load-bearing capacity, enhanced rigidity. |

| Main Tee Width (Flange) | 15 mm - 24 mm (0.59 - 0.94 in) | 24 mm (0.94 in) | Optimized for standard ceiling tile sizes, easy tile seating. |

| Cross Tee Length (Long) | 1200 mm (4 ft) | 1220 mm (4 ft) | Standard modular size for 60x60 cm or 2x4 ft tiles. |

| Cross Tee Length (Short) | 600 mm (2 ft) | 610 mm (2 ft) | Standard modular size for 60x60 cm or 2x2 ft tiles. |

| Cross Tee Height (Web) | 24 mm - 32 mm (0.94 - 1.26 in) | 32 mm (1.26 in) | Good load support for smaller tile spans. |

| Cross Tee Width (Flange) | 15 mm - 24 mm (0.59 - 0.94 in) | 24 mm (0.94 in) | Seamless integration with main tees, secure tile placement. |

| Wall Angle Length | 3000 mm - 3660 mm (10 ft - 12 ft) | 3660 mm (12 ft) | Consistent perimeter finish, strong wall attachment. |

| Thickness (Gauge) | 0.25 mm - 0.40 mm (28 - 25 Gauge) | 0.28 mm - 0.40 mm (Customizable) | Optimized for strength-to-weight ratio, preventing sag. |

| Load Bearing Capacity (Main Tee) | Up to 15 kg/m (e.g., ASTM C635 Heavy Duty) | Exceeds ASTM C635 Medium Duty (e.g., 9-10 kg/m typical for commercial) | Supports various ceiling tile types and integrated fixtures (lights, diffusers). |

| Fire Rating | Class A (non-combustible per ASTM E84) | Class A, compliant with relevant fire codes | Essential for safety in public and commercial buildings. |

| Corrosion Resistance | Excellent, due to galvanization | High-grade hot-dip galvanization for long-term protection | Suitable for humid environments, extends product life. |

| Recycled Content | Variable | Up to 25% (depending on steel source) | Contributes to LEED points and green building certifications. |

These specifications ensure that the Ceilings T Grid Suspended System is not just a support structure, but an integral part of a building's functional and safety profile. The meticulous engineering behind each component allows for the precise alignment and secure fit of ceiling panels, whether they are standard mineral fiber, gypsum, or more specialized panels affecting the overall gridstone ceiling tile cost and aesthetic.

Essential Components and Diverse Grid Ceiling Material Types

The beauty of a suspended ceiling system lies in its modularity and the variety of materials it can accommodate. The framework, primarily the ceiling t grid, forms the backbone, while the infill panels provide the aesthetic and functional performance.

- Main Tee: The longest and primary load-bearing component, suspended from the structural ceiling via wires. It features slots at regular intervals to connect cross tees. Its robust design is critical for the overall stability of the grid.

- Cross Tee: Shorter members that connect perpendicularly to the main tees, forming the grid squares or rectangles. There are typically two lengths: one for 2x4 ft or 600x1200 mm modules, and another for 2x2 ft or 600x600 mm modules. The interlocking mechanism ensures a secure and rigid connection.

- Wall Angle: An L-shaped perimeter trim that supports the edges of the ceiling tiles where they meet the wall. It provides a clean finish and additional support at the perimeter.

- Suspension Wires/Hangers: Galvanized steel wires or rods that connect the main tees to the overhead structural elements (e.g., concrete slab, steel beams). Their gauge and spacing are determined by the system's load-bearing requirements.

The choice of grid ceiling material for the tiles themselves is vast, each offering unique properties:

- Mineral Fiber: The most common, offering good acoustic properties, fire resistance, and affordability.

- Gypsum: Often vinyl-faced for enhanced moisture resistance and cleanability, ideal for restrooms or kitchens.

- Metal Panels: Aluminum or steel, often perforated for acoustics, offering a modern aesthetic and durability. They are highly resistant to moisture and mold.

- Wood Panels: Provide a warm, natural aesthetic, often used in executive offices or hospitality settings.

- Fiberglass: Lightweight, good acoustic absorbers, and often used in areas requiring high humidity resistance.

Figure 1: Illustration of a typical ceiling t grid installation, showcasing the interlocking components.

The Art and Science of Manufacturing: A Deep Dive into Ceilings T Grid Production

The manufacturing of high-quality ceiling t grid components is a testament to precision engineering and advanced material processing. At Xingyuan Ceilings, our process ensures every component meets stringent quality and performance standards, contributing to the overall durability and reliability of the Ceilings T Grid Suspended System. The core material is high-grade hot-dip galvanized steel, selected for its inherent strength and superior corrosion resistance.

Detailed Manufacturing Process Flow:

- Material Selection and Preparation:

- Material: The process begins with carefully selected coils of hot-dip galvanized steel, typically G60 (60g/m²) or G90 (90g/m²) coating weight for optimal corrosion protection. This material inherently offers a long usage lifespan due to its anti-corrosion properties.

- Inspection: Incoming steel coils undergo rigorous quality checks for gauge consistency, surface finish, and galvanization integrity.

- Uncoiling and Straightening:

- The galvanized steel coil is loaded onto an uncoiler, and the strip is fed through a straightening machine to remove any curvature or kinks, ensuring a flat and consistent profile for subsequent operations.

- Roll Forming (Cold Forming):

- This is the heart of the manufacturing process. The straightened steel strip passes through a series of precisely engineered rollers. Each pair of rollers progressively shapes the flat strip into the desired T-profile (for main tees and cross tees) or L-profile (for wall angles). This cold-forming process ensures high dimensional accuracy and enhances the material's strength without altering its metallurgical properties.

- Key Node: Roller Dies. The design and precision of these dies are critical for achieving the exact dimensions and consistent profile required for secure interlocking and load bearing.

- Punching and Notching:

- As the T-profile is formed, automated punching stations create the necessary holes and slots for interlocking connections (for cross tees) and suspension wire attachment points (for main tees). Precise notching is also done for end connections.

- Key Node: Automated Punching/Notching Machines. These machines ensure accurate hole placement and clean cuts, vital for easy assembly on site and maintaining structural integrity.

- Cutting to Length:

- Once the full profile and necessary features are formed, the continuous T-grid is cut to specified lengths (e.g., 3660mm for main tees, 1220mm and 610mm for cross tees) using high-speed, precision cutting mechanisms.

- Key Node: Flying Shears or Sawing Machines. These synchronized cutting tools ensure minimal material waste and highly accurate component lengths.

- End Treatment/Assembly (for Cross Tees):

- For cross tees, the ends are often crimped or fitted with pre-attached connectors, enabling quick and secure snap-in assembly with the main tees. This design facilitates the rapid installation of the cross tee ceiling.

- Quality Control and Inspection:

- Throughout the process, and especially after cutting, rigorous quality checks are performed.

- Dimensional Verification: Using calipers, micrometers, and optical measurement systems to ensure compliance with specified lengths, widths, heights, and thicknesses.

- Profile Integrity: Checking for any deformities, twists, or surface imperfections.

- Galvanization Assessment: Visual inspection and, occasionally, coating thickness tests to ensure uniform galvanization for corrosion resistance.

- Load Testing: Random samples may undergo destructive load testing to verify their load-bearing capacity against industry standards.

- Standards Compliance: Our products are continuously tested against international standards such as ISO 9001 for quality management, ASTM C635 (Standard Specification for Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings) and ASTM C636 (Standard Practice for Installation of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings) for performance and installation, and relevant GB/T standards in China (e.g., GB/T 11981-2008 for grid system for suspended ceiling).

- Throughout the process, and especially after cutting, rigorous quality checks are performed.

- Packaging:

- Finished ceiling t grid components are carefully bundled and packaged to prevent damage during transit and storage, typically in durable, moisture-resistant packaging.

This meticulous manufacturing process, leveraging cold-rolled forming and precision tooling, ensures that our ceiling t grid products possess exceptional structural integrity, consistent dimensions, and superior corrosion resistance. This translates directly into a product with an impressive usage lifespan, often exceeding 20-30 years in typical indoor environments, making it a sustainable and economical choice for long-term installations.

Figure 2: Precision roll-forming machines at Xingyuan Ceilings, demonstrating the advanced manufacturing of ceiling t grid components.

Diverse Application Scenarios and Unparalleled Advantages

The versatility of the ceiling t grid system makes it indispensable across a wide array of industries and building types. Its primary advantage lies in creating a plenum space above the finished ceiling, which efficiently houses critical building services.

- Commercial Offices and Corporate Buildings: Provides a clean, professional aesthetic while allowing easy access to HVAC ducts, electrical wiring, and data cables for maintenance or reconfigurations. Its ability to integrate with acoustic tiles significantly improves office productivity by reducing noise.

- Healthcare Facilities (Hospitals, Clinics): Demands for hygiene and specialized lighting are met. The smooth surfaces of compatible tiles are easy to clean, and the system allows for the integration of specialized medical equipment, air filtration systems, and even anti-microbial grid ceiling material. The modular nature also simplifies future upgrades.

- Educational Institutions (Schools, Universities): Offers excellent acoustic control to enhance learning environments, durability to withstand heavy use, and flexibility for installing various lighting and projection systems.

- Retail Spaces and Shopping Malls: Creates an open, inviting atmosphere while providing a flexible framework for displaying merchandise, installing spotlights, and accommodating frequent layout changes.

- Industrial and Manufacturing Plants: Ideal for environments that require robust, easy-to-clean ceilings. The galvanized steel construction offers superior corrosion resistance, making it suitable even in mildly aggressive environments, for instance, in light chemical processing zones. Its inherent fire resistance is crucial for safety compliance.

- Hospitality (Hotels, Restaurants): Contributes to sophisticated interior designs, offering options for various finishes and textures while providing access to mechanical systems above.

- Petrochemical and Metallurgy (Specific Areas): While direct exposure might require specialized solutions, in controlled auxiliary spaces or administrative buildings within these industries, the corrosion resistance of the galvanized ceiling t grid provides a durable and low-maintenance solution compared to alternative systems.

- Water Supply and Drainage Facilities (Control Rooms, Offices): In non-wet areas, the moisture resistance of galvanized steel and compatible tiles makes it a reliable choice, preventing issues like mold and rust that might plague less robust systems.

Technical Advantages of Xingyuan Ceilings' Ceilings T Grid Suspended System:

- Superior Corrosion Resistance: Our use of premium hot-dip galvanized steel ensures exceptional resistance to rust and oxidation, particularly vital in humid climates or environments where moisture is a concern. This significantly extends the product's lifespan and reduces maintenance costs.

- Exceptional Load-Bearing Capacity: Engineered to meet and often exceed ASTM C635 Medium Duty standards, our main tees and cross tee ceiling components can reliably support a wide range of ceiling tiles, light fixtures, diffusers, and other integrated systems without sagging or structural compromise.

- Precise Interlocking Design: The patented interlocking mechanism between main and cross tees ensures a secure, rigid, and perfectly aligned grid, simplifying installation and guaranteeing a flat, aesthetically pleasing finish. This precision contributes to faster project completion times.

- Fire Resistance: Manufactured from non-combustible galvanized steel, our T-grid system contributes to a Class A fire rating, enhancing building safety and compliance with stringent fire codes.

- Ease and Speed of Installation: The lightweight yet strong design, combined with intuitive interlocking features, allows for rapid assembly, significantly reducing labor time and overall project costs. This efficiency directly impacts the overall drywall ceiling grid price for contractors and end-users.

- Environmental Contribution: Utilizing steel with a high percentage of recycled content, our products align with green building initiatives and contribute to LEED certification, promoting sustainable construction practices.

- Versatile Compatibility: Designed to seamlessly integrate with a wide array of ceiling panel types, from standard mineral fiber to more specialized metal, gypsum, or acoustic panels, offering unparalleled design flexibility.

Strategic Manufacturer Comparison and Selection Criteria

Choosing the right ceiling t grid manufacturer is crucial for the success and longevity of any suspended ceiling project. While many manufacturers exist, distinguishing between them based on quality, service, and value is essential. Xingyuan Ceilings proudly stands out through a combination of superior product quality, extensive industry experience, and unwavering customer support.

Manufacturer Comparison Table (Illustrative):

| Criteria | Xingyuan Ceilings | Competitor A (Budget Focus) | Competitor B (Niche Focus) |

|---|---|---|---|

| Material Quality | Premium Hot-Dip Galvanized Steel (G60/G90 Equivalent) | Standard Galvanized Steel (Lower Coat Weight) | High-End Coated Steel (Specialty Finishes) |

| Manufacturing Process | Advanced Cold Roll Forming, High Precision Punching, ISO 9001 Certified | Standard Roll Forming, Less Precision, Variable QC | Specialized Roll Forming for Unique Profiles, High QC |

| Certifications & Standards | ISO 9001, ASTM C635/C636 Compliant, GB/T 11981-2008, third-party verified | Basic Industry Standards, Self-Certified | Specific Niche Certifications (e.g., European Standards) |

| Product Range | Comprehensive T-Grid (Standard & Metric), Wall Angles, Accessories, various compatible tiles. | Limited Standard T-Grid Sizes Only | Custom Profiles, Designer Series Grids |

| Corrosion Resistance | Excellent, Long Lifespan | Good, Standard Lifespan | Excellent, Often with Additional Coatings |

| Load Bearing Capacity | Exceeds Medium Duty (ASTM C635) | Meets Light/Medium Duty | Meets Heavy Duty (Specific Products) |

| Installation Ease | Highly Efficient Snap-in System | Standard Interlocking | Can be More Complex for Unique Designs |

| Customization Options | Flexible for thickness, length, and specific project needs. | Minimal | Extensive but at Higher Cost |

| Technical Support & After-Sales | Dedicated Team, Detailed Guides, Project Consultation, Global Support | Basic Support | Specialized Technical Consultancy |

| Typical Price Point (Relative to Market) | Competitive Mid-to-High (Value-Oriented) | Low-to-Mid (Cost-Oriented) | High-End Premium |

When considering the drywall ceiling grid price and the overall gridstone ceiling tile cost for a project, it's vital to look beyond the initial purchase price. A cheaper, lower-quality ceiling t grid might lead to higher long-term costs due to:

- Premature Deterioration: Inferior galvanization can lead to rust and structural failure, requiring costly replacements.

- Installation Difficulties: Inconsistent dimensions or poorly formed connections can slow down installation, increasing labor costs.

- Reduced Lifespan: A shorter product life means more frequent renovations and material purchases.

- Compromised Performance: Inadequate load-bearing capacity or fire rating can lead to safety hazards and non-compliance.

Xingyuan Ceilings prioritizes a balance of quality, performance, and value, ensuring that your investment in our Ceilings T Grid Suspended System yields long-term benefits and avoids hidden costs. Our extensive experience spanning decades in the industry positions us as a reliable partner for projects of any scale.

Tailored Solutions: Customization and Project-Specific Offerings

Recognizing that every construction project has unique requirements, Xingyuan Ceilings offers comprehensive customization solutions for our ceiling t grid systems. We understand that standard dimensions and specifications may not always fit the precise needs of innovative architectural designs or challenging structural constraints.

Our customization capabilities include:

- Gauge and Thickness Variation: While our standard offerings meet most needs, we can produce ceiling t grid components with specific steel gauges to accommodate extraordinary load requirements or to align with particular engineering specifications.

- Length Customization: For projects with non-standard room dimensions or unique grid layouts, we can manufacture main tees and cross tees in bespoke lengths, minimizing waste and simplifying on-site cutting.

- Coating Options: Beyond standard galvanization, we can explore additional protective coatings for highly corrosive environments, though hot-dip galvanization typically suffices for most applications, offering superior long-term anti-corrosion properties.

- Specialized Finishes: While the T-grid is largely concealed by ceiling tiles, certain exposed applications or design preferences may call for specific paint or powder coatings, which can be arranged.

- Integrated Solutions: Our team can work with project managers and architects to integrate the T-grid system seamlessly with other ceiling elements, such as specialized lighting fixtures, advanced HVAC diffusers, or unique access panels. This includes providing guidance on supporting heavy or custom grid ceiling material panels.

Our dedicated engineering and sales teams collaborate closely with clients from the design phase through to delivery, ensuring that the customized solutions are perfectly aligned with project goals, budget constraints, and delivery timelines. This consultative approach has been a cornerstone of our success, enabling us to support a diverse portfolio of complex and high-profile projects worldwide.

Real-World Impact: Application Cases and Success Stories

The reliability and versatility of Xingyuan Ceilings' ceiling t grid systems are best exemplified through their successful deployment in numerous prestigious projects across various sectors. These case studies highlight the practical advantages and long-term benefits of choosing our premium suspension systems.

Case Study 1: Large-Scale Commercial Office Complex, Downtown Business District

- Challenge: To provide a robust, aesthetically pleasing, and easily accessible ceiling system for over 500,000 sq ft of office space, incorporating extensive data cabling, smart lighting, and variable HVAC zones. The project also had a tight deadline and a need for consistent quality across all phases.

- Solution: Xingyuan Ceilings supplied its standard 24mm flange ceiling t grid system, primarily with 2x4 ft modules, complemented by premium mineral fiber acoustic tiles. The system's snap-in assembly and consistent dimensions significantly accelerated installation, allowing contractors to meet aggressive schedules.

- Outcome: The project was completed on time and within budget. The client reported exceptional acoustic performance, enhanced indoor air quality facilitated by the integrated HVAC, and the flexibility to reconfigure office layouts without extensive ceiling rework. The inherent durability of the galvanized cross tee ceiling ensured long-term structural stability, minimizing future maintenance costs.

Case Study 2: State-of-the-Art Hospital Wing, Major Metropolitan Area

- Challenge: A new hospital wing required ceilings that met stringent hygiene standards, fire safety regulations, and superior sound attenuation, while allowing easy access for medical gas lines, electrical conduits, and ventilation systems. Durability against constant cleaning and disinfectant exposure was also critical.

- Solution: Xingyuan Ceilings provided a specialized version of its ceiling t grid system, coupled with vinyl-faced gypsum tiles for enhanced moisture resistance and cleanability. The galvanized steel of the T-grid ensured excellent corrosion resistance, even in areas with high humidity or frequent cleaning cycles. The system's design allowed for seamless integration of specialized lighting for operating theaters and patient rooms.

- Outcome: The hospital wing successfully passed all regulatory inspections, achieving high scores for hygiene and safety. The ease of access provided by the ceiling t grid system has simplified maintenance of critical overhead utilities, and the robust construction ensures a long service life in a demanding environment. The selection of materials also positively influenced the long-term gridstone ceiling tile cost by reducing replacement frequency.

Figure 3: A completed interior featuring Xingyuan Ceilings' ceiling t grid system, demonstrating a clean, modern aesthetic and robust support for various ceiling tiles.

Ensuring Unwavering Quality: Certifications, Standards, and Testing

At Xingyuan Ceilings, our commitment to quality is not just a promise; it's ingrained in every stage of our operations. This unwavering dedication is demonstrated through our adherence to rigorous international standards, comprehensive internal testing, and independent third-party certifications. These measures provide our clients with the confidence and assurance that they are investing in products of the highest caliber, reflecting our Authoritativeness in the industry.

- ISO 9001:2015 Certification: Our manufacturing processes are certified under ISO 9001:2015, the internationally recognized standard for Quality Management Systems. This ensures consistent product quality, continuous improvement, and customer satisfaction throughout the entire production chain.

- ASTM Standards Compliance: Our ceiling t grid systems are designed and tested to meet or exceed relevant ASTM International standards, including:

- ASTM C635/C635M: Standard Specification for Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings. This standard dictates requirements for load-bearing capabilities, deflection limits, and material properties.

- ASTM C636/C636M: Standard Practice for Installation of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings. While a practice guide, our product design facilitates compliance with proper installation techniques.

- ASTM E84: Standard Test Method for Surface Burning Characteristics of Building Materials. Our galvanized steel components contribute to a Class A flame spread and smoke development rating, vital for fire safety.

- GB/T Standards: As a leading manufacturer, we also adhere to Chinese national standards such as GB/T 11981-2008 (Suspended ceiling grid system for buildings), ensuring our products meet local and international benchmarks for performance and safety.

- Internal Quality Control: Beyond external certifications, we implement a multi-stage internal quality control protocol. This includes raw material inspection, in-process checks at each manufacturing stage (e.g., thickness, width, length, hole punching accuracy), and final product inspection for finish, profile integrity, and packaging. Statistical process control (SPC) techniques are employed to maintain consistency.

- Load-Bearing Capacity Testing: Random samples from production batches undergo simulated load testing to verify their resistance to deflection and ultimate failure under various load conditions, ensuring that our products can safely support the intended ceiling tiles and integrated fixtures.

- Corrosion Resistance Testing: Salt spray tests and humidity chamber tests are periodically conducted on galvanized samples to confirm the longevity and effectiveness of the protective coating, extending the product's lifespan.

Our commitment to these stringent standards and rigorous testing protocols underscores our Authoritativeness in the ceiling industry, providing clients with unparalleled product reliability and peace of mind.

Building Trust: FAQ, Delivery, Warranty, and Customer Support

At Xingyuan Ceilings, Trustworthiness is a core tenet of our business philosophy. We believe in transparent communication, reliable service, and comprehensive support to ensure complete customer satisfaction. From pre-sales consultation to post-installation assistance, we are dedicated to being a dependable partner.

Frequently Asked Questions (FAQ)

- What is the primary material used for Xingyuan Ceilings' T-grid systems?

Our ceiling t grid systems are primarily manufactured from high-grade hot-dip galvanized steel, ensuring excellent strength, durability, and superior corrosion resistance for long-term performance. - How does the galvanization process benefit the T-grid?

Hot-dip galvanization applies a protective zinc coating to the steel, which acts as a barrier against rust and corrosion, significantly extending the product's lifespan, especially in humid or corrosive environments. - Are your T-grid systems compatible with all types of ceiling tiles?

Yes, our Ceilings T Grid Suspended System is designed for universal compatibility with most standard ceiling tile types, including mineral fiber, gypsum, metal, and acoustic panels, facilitating diverse design choices and optimizing the overall gridstone ceiling tile cost. - What is the typical lifespan of a Xingyuan Ceilings T-grid system?

With proper installation and maintenance, our galvanized ceiling t grid systems are engineered for a long usage lifespan, typically exceeding 20-30 years in normal indoor environments, due to their robust material and manufacturing quality. - Do your products meet international quality and safety standards?

Absolutely. Our manufacturing processes are ISO 9001 certified, and our products meet or exceed international standards such as ASTM C635/C636 and contribute to Class A fire ratings (ASTM E84), ensuring compliance and safety. - How does the snap-in design of the cross tee ceiling improve installation?

The precision-engineered snap-in connection for our cross tee ceiling components allows for quick, secure, and tool-free attachment to the main tees. This significantly reduces installation time and labor costs, making the overall drywall ceiling grid price more cost-effective. - Can Xingyuan Ceilings provide customized T-grid lengths or specifications?

Yes, we offer flexible customization options for specific project requirements, including variations in gauge (thickness), length, and certain finishes, to ensure our products perfectly align with unique architectural designs and structural needs.

Delivery and Logistics

We understand the critical importance of timely delivery for construction projects. Xingyuan Ceilings maintains efficient production schedules and robust logistics partnerships to ensure your ceiling t grid orders are processed and shipped promptly and reliably. Our typical lead times vary based on order volume and customization requirements but are communicated clearly upfront. We offer various shipping options to accommodate urgent deliveries and international destinations, with comprehensive packaging designed to protect products during transit.

Warranty and Quality Assurance

Xingyuan Ceilings stands behind the quality and performance of our Ceilings T Grid Suspended System. We offer a comprehensive limited warranty against manufacturing defects and material failures under normal use and installation conditions. This warranty reflects our confidence in our products' durability and our commitment to customer satisfaction. Specific warranty terms and conditions are available upon request and are detailed in our sales agreements.

Customer Support and Technical Assistance

Our dedicated customer support team is available to assist you at every stage of your project. Whether you need pre-sales consultation, technical specifications, installation guidance, or after-sales support, our experienced professionals are ready to help. We provide:

- Product Selection Assistance: Guiding you through the best T-grid system and compatible grid ceiling material for your specific application.

- Technical Documentation: Providing detailed product sheets, installation guides, and performance data.

- Project-Specific Consultation: Working with your engineers and architects to ensure optimal system design and integration.

- Troubleshooting Support: Addressing any challenges that may arise during installation or use.

Our commitment to excellence extends beyond the product itself, encompassing a service experience that builds lasting partnerships.

In conclusion, the ceiling t grid is more than just a structural component; it is the backbone of modern, adaptable, and high-performing suspended ceiling systems. The Ceilings T Grid Suspended System from Xingyuan Ceilings exemplifies superior quality, precision engineering, and a commitment to meeting the diverse needs of contemporary architecture and construction. By combining robust materials, advanced manufacturing processes, and adherence to global standards, we deliver solutions that are not only aesthetically pleasing but also offer unparalleled durability, safety, and long-term value, proving to be a smart investment that optimizes the overall drywall ceiling grid price by reducing future maintenance and replacement costs. Our dedication to principles ensures that you receive not just a product, but a comprehensive solution backed by expertise, experience, authority, and trustworthiness.

References and Further Reading:

- Industry Forum Discussion on Suspended Ceiling Trends: Construction Forum - Suspended Ceilings: Innovations and Market Outlook 2024

- Academic Journal Article on Galvanized Steel in Construction: Journal of Materials Engineering - Durability and Performance of Galvanized Steel in Building Applications

- Global Suspended Ceiling Market Analysis (Sample Report): Market Research Reports Inc. - Global Suspended Ceiling Market Research Report (2023-2030)

-

Mineral Fiber Ceiling Tiles Embossed Surface PatternNewsAug.05,2025

-

Mineral Fiber Board Xingyuan Vision for Better SpacesNewsAug.05,2025

-

Drop Down Ceiling Tile Office Use FitNewsAug.05,2025

-

PVC Gypsum Ceiling White Base ColorNewsAug.05,2025

-

Access Panel on Ceiling Xingyuan Integrity EthicNewsAug.05,2025

-

Ceiling Trap Doors Fire Resistant DesignNewsAug.05,2025