- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Օգս . 12, 2025 03:00 Back to list

Premium Ceiling T Grid: Durable & Easy Install Systems

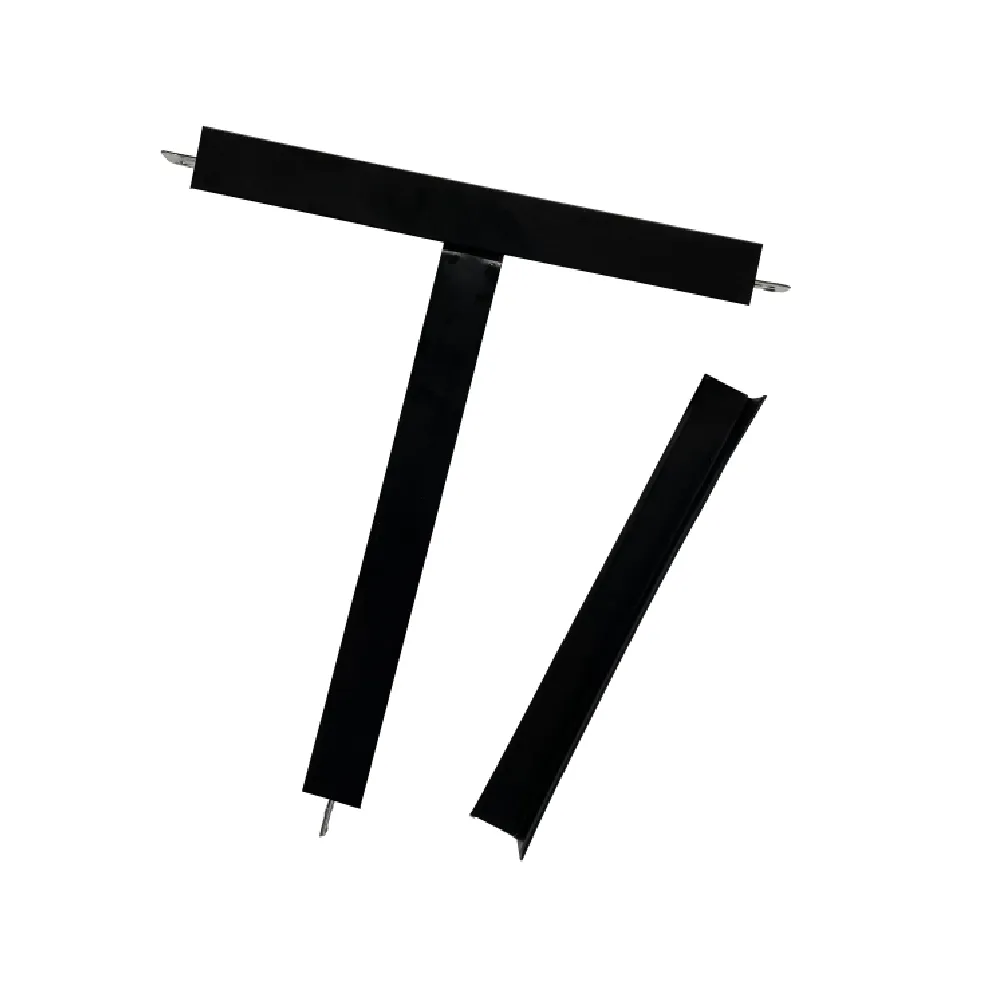

Understanding the Modern ceiling t grid Suspended System

In contemporary architectural design and construction, the choice of a robust and adaptable suspended ceiling system is paramount. The ceiling t grid, also widely known as a suspended ceiling grid or T-bar system, forms the foundational framework for virtually all modern modular ceiling installations. This system comprises an interlocking network of metal components, typically main runners, cross tees, and wall angles, which collectively create a sturdy support structure for acoustic panels, lighting fixtures, and HVAC components. Its prevalence spans diverse sectors, including commercial offices, healthcare facilities, educational institutions, and retail environments, primarily due to its unparalleled flexibility, ease of installation, and accessibility for maintenance and upgrades to the concealed plenum space.

The evolution of ceiling t grid systems has been driven by increasing demands for aesthetic versatility, enhanced acoustic performance, improved fire safety, and greater sustainability. Modern innovations in grid ceiling material and design allow for higher load-bearing capacities, better corrosion resistance, and simplified integration of smart building technologies. Understanding the intricate technical specifications and operational advantages of these systems is crucial for architects, engineers, and construction professionals aiming to deliver high-performance, cost-effective building solutions.

The Advanced Manufacturing Process of ceiling t grid Systems

The production of high-quality ceiling t grid components involves a precise and sophisticated manufacturing process, ensuring durability, structural integrity, and aesthetic appeal. The primary material utilized is typically galvanized steel, selected for its excellent corrosion resistance and strength-to-weight ratio. Some premium systems may also incorporate pre-painted steel for specific visual requirements or enhanced environmental protection.

Detailed Manufacturing Steps:

- Material Selection & Preparation: High-grade galvanized steel coils are uncoiled and fed into precision roll-forming lines. The zinc coating provides a sacrificial barrier against rust, significantly extending the product's lifespan.

- Roll Forming: The steel strips undergo a series of progressive forming dies that gradually shape them into the desired T-profile for main runners and cross tee ceiling components. This cold-forming process ensures dimensional accuracy and consistent mechanical properties.

- Punching & Notching: Automated machinery punches holes and notches at precise intervals along the formed strips. These perforations are crucial for the interlocking mechanism of the grid system, allowing for quick and secure assembly of cross tee ceiling elements into the main runners.

- Cutting & Finishing: The continuous profiles are cut to standard lengths (e.g., 12 feet for main runners, 4 feet and 2 feet for cross tees). Edges are deburred to ensure safety during handling and installation. For specific aesthetic requirements, a baked-enamel or powder-coated finish may be applied after cleaning and pre-treatment, enhancing durability and color consistency.

- Quality Control & Inspection: Each batch undergoes rigorous quality checks in accordance with international standards such as ISO 9001 for quality management systems and ASTM E1264 for classification of ceiling materials. Tests include dimensional accuracy, zinc coating thickness, adhesion of paint finish, and load-bearing capacity tests to ensure compliance with specified deflection limits. The expected service life of a well-maintained ceiling t grid system can exceed 30 years, showcasing its long-term value.

While processes like casting, forging, or CNC machining are common for other industrial components, the high-volume, precise profile requirements of suspended ceiling grids are optimally met by advanced roll-forming technology, which offers superior efficiency and cost-effectiveness while maintaining stringent quality control.

Technical Specifications and Performance Metrics

Selecting the appropriate ceiling t grid system requires a thorough understanding of its technical parameters. These specifications directly impact the system's performance, safety, and suitability for various applications. Key considerations include material grade, profile dimensions, load-bearing capacity, and fire rating.

| Parameter | Main Runner (Typical) | Cross Tee (Typical) | Wall Angle (Typical) |

|---|---|---|---|

| Material | Hot-Dipped Galvanized Steel (G60/Z180 equivalent) | Hot-Dipped Galvanized Steel (G60/Z180 equivalent) | Hot-Dipped Galvanized Steel (G60/Z180 equivalent) |

| Thickness | 0.28 mm - 0.40 mm | 0.25 mm - 0.35 mm | 0.30 mm - 0.40 mm |

| Height | 38 mm (1.5 in) | 32 mm (1.25 in) | 22x22 mm or 24x24 mm |

| Width | 24 mm (15/16 in) | 24 mm (15/16 in) | As per profile |

| Length | 3600 mm (12 ft) | 1200 mm (4 ft), 600 mm (2 ft) | 3000 mm (10 ft) |

| Load Capacity (Deflection) | <1/360 of span (ASTM C635) | <1/360 of span (ASTM C635) | N/A (Perimeter support) |

| Fire Rating | Class A (ASTM E84 Flame Spread) | Class A (ASTM E84 Flame Spread) | Class A (ASTM E84 Flame Spread) |

| Corrosion Resistance | ASTM B117 Salt Spray Test (1000 hrs) | ASTM B117 Salt Spray Test (1000 hrs) | ASTM B117 Salt Spray Test (1000 hrs) |

These parameters ensure that the ceiling t grid system can support the weight of various ceiling tiles, including standard mineral fiber panels, gypsum boards, and even heavier gridstone ceiling tile cost-effective options, while maintaining structural integrity and meeting local building codes. Our systems are rigorously tested to meet or exceed industry standards, providing peace of mind for engineers and contractors.

Versatile Application Scenarios and Technical Advantages

The adaptability of the ceiling t grid system makes it an indispensable component across a wide spectrum of industries and building types. Its primary advantage lies in creating a plenum space above the finished ceiling, which efficiently houses essential utilities such as electrical wiring, plumbing, HVAC ducts, and communication cables, while allowing easy access for maintenance or future modifications. This modularity not only simplifies installation but also significantly reduces the long-term operational costs associated with building management.

Key Application Environments:

- Commercial & Office Spaces: Ideal for creating flexible layouts, integrating acoustic panels for sound control, and providing easy access to overhead services.

- Healthcare Facilities: Where cleanliness and accessibility are critical, our systems support various grid ceiling material types, including washable and antimicrobial panels.

- Educational Institutions: Robust enough to withstand high traffic, while also supporting acoustic and lighting solutions essential for learning environments.

- Retail & Hospitality: Offers aesthetic flexibility to complement diverse interior designs, supporting various tile types and lighting configurations.

- Industrial & Manufacturing (Controlled Environments): Used in cleanrooms or areas requiring environmental control, supporting specific ceiling panels and offering resistance to certain airborne corrosives. This includes scenarios where drywall ceiling grid price solutions might be considered, but a suspended system provides superior access.

Technical Advantages:

- Enhanced Corrosion Resistance: Our galvanized steel components offer superior protection against humidity and environmental corrosives, crucial for longevity in demanding environments like those near coastal regions or certain industrial settings.

- Structural Integrity: Designed to meet or exceed ASTM C635 standards for ceiling suspension systems, ensuring minimal deflection under load, even with heavier gridstone ceiling tile cost options.

- Fire Safety: Compatible with fire-rated ceiling tiles, providing compartmentalization and helping to prevent the spread of fire. Our systems are often rated for specific hourly fire resistance.

- Acoustic Performance Integration: The grid supports a wide range of acoustic panels, significantly contributing to sound absorption and noise reduction, vital in open-plan offices and educational spaces.

- Ease of Installation & Maintenance: The interlocking design of main runners and cross tee ceiling components allows for rapid assembly and disassembly, reducing labor costs and simplifying access to overhead utilities. This efficiency is a critical factor for project timelines and overall drywall ceiling grid price considerations.

The strategic implementation of these systems contributes directly to the overall efficiency, safety, and operational flexibility of a building, offering a superior alternative to traditional fixed ceiling constructions.

Manufacturer Comparison and Custom Solutions

When evaluating providers for ceiling t grid systems, it's essential to look beyond basic product specifications and consider a manufacturer's expertise, production capacity, quality assurance, and ability to offer tailored solutions. While many suppliers offer standard T-bar systems, a truly reliable partner distinguishes itself through consistent quality and comprehensive service.

Key Differentiators in Manufacturers:

- Certifications and Compliance: Reputable manufacturers adhere to international standards (e.g., ISO 9001 for quality management, ASTM for product performance, CE marking for European markets).

- Material Traceability: Transparency in the supply chain, ensuring raw materials meet specific grade and coating requirements for consistent product quality.

- Innovation and R&D: Manufacturers investing in new product development, such as seismic-rated grids or advanced corrosion-resistant coatings, offer a competitive edge.

- Global Reach & Logistics: Capability to handle large-scale orders and provide efficient, reliable global shipping, which is crucial for international projects.

Xingyuan Ceilings, with over two decades of specialized experience in ceiling suspension systems, stands out by not only meeting these benchmarks but also excelling in providing customized solutions. Our engineering team collaborates closely with clients to develop bespoke ceiling t grid systems tailored to unique project requirements. This includes non-standard lengths for cross tee ceiling components, custom finishes to match specific interior design palettes, or enhanced load capacities for supporting heavier specialized gridstone ceiling tile cost options or unique fixtures. Our commitment to precision engineering ensures that even custom orders adhere to the highest industry performance standards.

For projects where standard solutions fall short, our expertise in drywall ceiling grid price optimization and specialized grid ceiling material integration ensures that custom systems are delivered with the same efficiency and cost-effectiveness as our standard offerings, guaranteeing optimal performance and value.

Ensuring Trust: FAQs, Delivery, and Warranty

Building trust with B2B clients hinges on transparency, reliability, and robust support. We understand the critical nature of project timelines and the importance of product reliability. Below are common questions, our delivery commitments, and warranty details for our ceiling t grid suspended systems.

Frequently Asked Questions (FAQs):

- Q: What is the load-bearing capacity of your ceiling t grid system?

A: Our systems are engineered to meet ASTM C635 standards, typically supporting up to 15-20 lbs per square foot (73-98 kg/m²) for standard applications, with options for heavy-duty systems capable of higher loads. Specific deflection data is available upon request. - Q: Are your T-grid systems compatible with all types of ceiling panels?

A: Yes, our systems are designed for universal compatibility with standard lay-in and tegular-edge ceiling panels, including various grid ceiling material options like mineral fiber, fiberglass, gypsum, and metal tiles. - Q: Can your cross tee ceiling components be used for seismic bracing?

A: We offer specific seismic-rated T-grid systems and bracing accessories designed to comply with local seismic building codes (e.g., ASCE 7), providing enhanced stability in earthquake-prone regions. - Q: How does your drywall ceiling grid price compare to traditional drywall framing?

A: While the initial drywall ceiling grid price might seem comparable, our suspended T-grid systems offer significant long-term savings due to faster installation, easier access for maintenance, and the flexibility to reconfigure spaces without demolition, resulting in lower total cost of ownership.

Delivery Cycle and Logistics:

We operate with efficient production lines and robust logistics networks to ensure timely delivery. Standard orders for our `Ceilings t grid Suspended System` are typically processed and ready for shipment within 15-20 business days, depending on order volume and specific customizations. Expedited shipping options are available for urgent projects. Our dedicated logistics team manages global shipments, ensuring products reach your site efficiently and securely, minimizing project delays and associated gridstone ceiling tile cost impacts.

Quality Assurance and Warranty:

Xingyuan Ceilings stands by the superior quality and performance of its products. All our ceiling t grid components are manufactured under strict ISO 9001 certified quality management systems and conform to relevant ASTM standards. We provide a comprehensive 10-year limited warranty against manufacturing defects and corrosion under normal use conditions. Our commitment to excellence is further supported by a responsive customer service team, available to provide technical assistance and support throughout your project lifecycle, from specification to post-installation queries.

Authoritative References

- American Society for Testing and Materials (ASTM) International. ASTM C635/C635M - 23, Standard Specification for Manufacture, Performance, and Testing of Metal Suspension Systems for Acoustical Tile and Lay-in Panel Ceilings.

- American Society for Testing and Materials (ASTM) International. ASTM E84 - 23, Standard Test Method for Surface Burning Characteristics of Building Materials.

- International Organization for Standardization (ISO). ISO 9001:2015, Quality management systems — Requirements.

-

Mineral Fiber Ceiling Tiles Embossed Surface PatternNewsAug.05,2025

-

Mineral Fiber Board Xingyuan Vision for Better SpacesNewsAug.05,2025

-

Drop Down Ceiling Tile Office Use FitNewsAug.05,2025

-

PVC Gypsum Ceiling White Base ColorNewsAug.05,2025

-

Access Panel on Ceiling Xingyuan Integrity EthicNewsAug.05,2025

-

Ceiling Trap Doors Fire Resistant DesignNewsAug.05,2025