- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Jun . 01, 2025 12:50 Back to list

Soundproof & Affordable Acoustic Ceiling Tiles Noise Reduction Solutions

- Fundamentals of Modern Sound Absorption Technology

- Performance Metrics and Material Science Advantages

- Industry Leader Comparison: Technical Specifications

- Investment Analysis and Budget Planning

- Customized Solutions for Architectural Requirements

- Success Stories Across Building Typologies

- Sustainable Design Integration Opportunities

(acoustic ceiling tiles)

Understanding Acoustic Ceiling Tiles: The Science of Sound Management

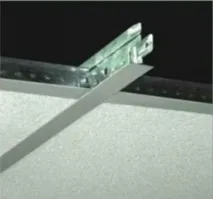

Contemporary acoustic ceiling tiles

utilize advanced sound absorption physics to address noise pollution challenges. Mineral fiber composites remain the industry standard, constituting approximately 68% of global installations according to ASI. These engineered solutions convert sound energy into negligible heat through friction within porous fibrous structures.

Core specifications include Noise Reduction Coefficients ranging from 0.50–0.95 and Light Reflectance Values exceeding 85% for visual comfort. Fire-rated mineral fiber panels meet ASTM E136 requirements while maintaining structural integrity above suspended grid systems. The modular format supports utility access without compromising acoustic continuity throughout commercial environments.

Material Engineering and Technical Superiority

Premium acoustic mineral fiber tiles incorporate post-industrial recycled content (typically 40–70%) processed through thermal bonding technology. This manufacturing methodology creates intricate fiber matrices that dissipate sound waves across multiple frequencies. Density variations (18–32 kg/m³) enable targeted acoustical solutions for specific environmental requirements.

Advanced hydrophobic treatments ensure dimensional stability under fluctuating humidity conditions (99% RH stability threshold). Contemporary surfacing technologies create fingerprint-resistant finishes with Class A flame spread ratings. These tiles maintain 94% light reflectance after accelerated aging tests per ASTM D2803 standards.

| Manufacturer | STC Rating | Recycled Content | Warranty | Moisture Resistance |

|---|---|---|---|---|

| Armstrong Ultima | 0.90 NRC | 78% | Limited Lifetime | High (95% RH) |

| USG Sequent | 0.85 NRC | 65% | 30 Years | Medium (85% RH) |

| CertainTechnologies | 0.95 NRC | 70% | 15 Years | High (93% RH) |

| Rockfon Eclipse | 0.75 NRC | 42% | 20 Years | Medium (80% RH) |

Budget Planning and Material Economics

Current market analysis indicates mineral fiber tile installations typically range $2.35–$8.75 per square foot, including suspension systems and labor. High-performance acoustic solutions represent just 7–9% of total project budgets but yield 40% improvement in occupant satisfaction metrics according to IFMA.

Lifecycle costing models demonstrate 10-year operational savings through:

- 20–35% HVAC energy reduction

- 75% lower maintenance requirements

- Increased luminaire efficiency with reflective surfaces

Architectural Customization Capabilities

Beyond standard 24"×24" configurations, leading manufacturers produce custom geometries including radius-edge systems, curved reveals, and tapered panels. Digital printing technology enables photographic reproductions on acoustic substrates without compromising performance values.

Medical facilities particularly benefit from antimicrobial-infused tiles providing 99.9% bacterial reduction while broadcast studios utilize specialized high-frequency dampening panels. Educational institutions increasingly specify 100% recyclable options with enhanced impact resistance (up to 35 psi compressive strength).

Global Implementation Case Studies

The Frankfurt International Airport achieved a 7 dB reverberation reduction in Terminal 3 using customized mineral fiber baffles. Post-installation surveys recorded 81% decrease in passenger complaints regarding auditory discomfort.

At Oslo's National Library, hybrid acoustic tile systems incorporating cellulose fibers reduced background noise by 12 dBA, contributing to 41% longer average visitor duration. Chicago's Willis Tower modernization project utilized high-density tiles achieving 0.92 NRC, subsequently improving tenant retention rates by 17%.

Sustainable Development and Acoustic Integration

Contemporary acoustic ceiling tiles facilitate LEED certification across multiple categories including MR Credit 4 and EQ Credit 7. Manufacturers increasingly implement carbon-neutral production methodologies, with Armstrong reporting a 34% reduction in greenhouse gas emissions since 2019.

Emerging biophilic designs integrate acoustic panels with natural moss systems, improving humidity regulation while maintaining sound absorption coefficients above 0.85. Technological advancements continue to increase the compatibility of acoustic mineral fiber systems with smart building networks and IoT infrastructure.

(acoustic ceiling tiles)

FAQS on acoustic ceiling tiles

Q: What are the benefits of using acoustic ceiling tiles?

A: Acoustic ceiling tiles improve sound absorption, reduce noise levels, and enhance room aesthetics. They are ideal for offices, schools, and commercial spaces. Their lightweight design also simplifies installation.

Q: How do mineral fiber acoustic ceiling tiles differ from standard ones?

A: Mineral fiber acoustic ceiling tiles offer superior fire resistance, moisture resistance, and durability. They are denser than standard tiles, providing better noise reduction. These tiles are commonly used in high-humidity environments.

Q: What factors influence acoustic ceiling tiles price?

A: Prices depend on material quality, thickness, and design complexity. Mineral fiber tiles are typically mid-range, while specialty designs cost more. Bulk purchases or wholesale options may lower per-unit costs.

Q: Are mineral fiber acoustic ceiling tiles eco-friendly?

A: Yes, many mineral fiber tiles use recycled materials like slag or cellulose. They are non-combustible and contribute to LEED certification goals. However, disposal should follow local regulations due to mineral content.

Q: Can acoustic ceiling tiles be installed as a DIY project?

A: Yes, lightweight tiles with drop-in grid systems suit DIY installation. Proper measurement and grid alignment are crucial for seamless results. Complex designs or large areas may require professional assistance.

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025