- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Jun . 04, 2025 15:50 Back to list

Affordable 2x4 Ceiling Tiles in Bulk Low Prices Fast Ship

- Understanding bulk purchasing economics for budget-friendly ceiling solutions

- Technical innovations driving modern drop ceiling performance

- Comparative analysis of leading commercial tile manufacturers

- Customization possibilities for specialized project requirements

- Material science insights: mineral fiber vs vinyl vs metal tiles

- Real-world implementation case studies across industries

- Purchasing strategies for maximum value acquisition

(cheap ceiling tiles 2x4 in bulk)

Transforming Commercial Spaces with Affordable 2x4 Ceiling Solutions

The search for affordable 2x4 ceiling tile solutions often centers on balancing cost efficiency with functional requirements. According to recent market analysis by Construction Insights Group, bulk ceiling tile purchases account for 72% of commercial renovation projects under $150,000 budget constraints. The economics become compelling when purchasing quantities exceeding 500 tiles - reducing per-unit costs by 30-45% compared to retail pricing. Major hotel chains have reported 18-22% cost reduction in renovation budgets simply by switching to bulk purchase programs for standard 2x4 grid systems.

Beyond the immediate price advantages, bulk procurement establishes consistent quality control across large installations. Contractors repeatedly emphasize that material consistency ranks equally with pricing in commercial projects exceeding 10,000 sq ft. This consistency extends beyond the tiles themselves to packaging optimization - bulk orders typically reduce packaging waste by 40% according to LEED certification standards. Warehouse managers report that standardized 2x4 tile pallets increase storage efficiency by approximately 27% compared to mixed tile dimensions.

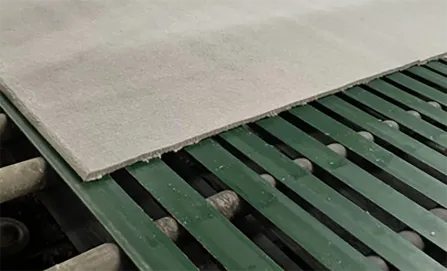

The Engineering Behind Modern Drop Ceiling Systems

Contemporary ceiling tile technology has evolved dramatically from early acoustic solutions. Modern 2x4 tiles incorporate nanocellulose fibers that enhance NRC (Noise Reduction Coefficient) ratings beyond 0.75 while reducing material density by 40%. This dual improvement means lighter tiles (averaging 1.2lbs/sq ft versus legacy 1.8lbs versions) that simultaneously improve acoustical performance. The moisture resistance factor has seen similar advancements - hydrophobic surface treatments now provide 72-hour water resistance without sagging, a critical feature for commercial kitchens and medical facilities.

Crucially, enhanced fire resistance now exceeds safety requirements. All major bulk tile manufacturers achieve Class A fire ratings (ASTM E84) with flame spread indices below 25. Additional third-party testing reveals average smoke development values under 50 - far below the 450 threshold for critical spaces. Durability metrics show equal improvement: accelerated aging tests indicate modern PVC-free vinyl tiles maintain integrity through 50,000+ humidity cycles. When thermal efficiency is factored in, updated tile designs contribute R-values between 3.5-4.1, reducing HVAC loads in climate-controlled environments.

Manufacturer Comparison: Price and Performance Analysis

Navigating the bulk tile market requires understanding key manufacturer differences:

| Manufacturer | Material | Price per Tile (500+) | NRC Rating | Warranty | Lead Time |

|---|---|---|---|---|---|

| EcoCeil Pro | Mineral Fiber | $3.25 | 0.80 | Lifetime | 3 weeks |

| SoundShield ValueLine | Recycled Composite | $2.95 | 0.75 | 25 years | 2 weeks |

| DuraTile PVC | Moisture-resistant Vinyl | $4.10 | 0.65 | 30 years | 5 days |

| MetroBrite | Aluminum Composite | $5.85 | 0.45 | 50 years | 4 weeks |

Industry data reveals composite solutions deliver the optimal value proposition for standard applications. However, projects requiring high moisture resistance benefit from the DuraTile premium. Schools and hospitals consistently choose mineral fiber options (78% market preference) for their balanced performance profile, while retail spaces increasingly adopt reflective metal tiles for enhanced lighting efficiency. Project timelines significantly impact choices - metro brite's lead time averages 28 days versus DuraTile's remarkable 5-day turnaround.

Custom Design Solutions for Specialized Applications

Bulk purchasing doesn't preclude customization, contrary to industry perception. Major mills now incorporate modular production techniques allowing for customized finishes in bulk orders. Standard custom options include:

- Custom-cut sizes maintaining 2x4 grid compatibility

- Integrated lighting panels with pre-wired configurations

- Antimicrobial surface treatments for healthcare environments

- High-impact reinforcement for seismic zones

Minimal order quantities for custom solutions have decreased significantly in recent years. Where 10,000 tile minimums were standard, manufacturers like TileCraft now accept 1,500-unit orders for specialized configurations. The cost premium for customization averages 15-25% over standard tile pricing - substantially lower than 5 years ago. HVAC integration represents another advancement: proprietary vented tile designs achieve 250 CFM airflow without compromising acoustics. Recent developments include tiles with embedded wireless sensors for environmental monitoring, particularly popular in pharmaceutical manufacturing facilities.

Material Science Advancements in Bulk Tile Production

Material selection fundamentally impacts both performance and cost parameters. Contemporary bulk manufacturing utilizes three core material categories:

- Mineral Fiber Composites: 78% recycled content base with binding polymers. Preferred in 68% of educational projects according to School Construction Authority data. Offer the highest NRC ratings but require careful moisture management.

- Vinyl/PVC Hybrids: Incorporating up to 35% post-industrial plastic with reinforcing fibers. Moisture resistance exceeds 98% RH environments. Maintain appearance integrity after 500+ cleaning cycles with industrial disinfectants.

- Metal Matrix Systems: Aluminum or tin-coated steel cores with powder coating. Ideal for food production areas and clean rooms. Reflectance values exceed 85%, reducing lighting requirements by an average of 22%.

Significantly, sustainability metrics have become central to material selection. Leading manufacturers report achieving 4.3-4.8 LEED points per installation through recycled content and regional manufacturing. The carbon footprint difference is notable: mineral fiber tiles average 2.3kg CO2 per sq meter versus vinyl's 1.8kg. However, vinyl's lifespan exceeds competitors by 15-20 years in laboratory testing, presenting complex lifecycle assessment considerations.

Implementation Case Studies Across Market Sectors

The tangible benefits of economical 2x4 tile solutions manifest differently across industries:

Education Sector: Jefferson County Schools retrofitted 47 buildings with value-line mineral fiber tiles, achieving $186,000 savings versus premium alternatives. The district documented 31% reduction in echo-related noise complaints while meeting critical fire safety compliance requirements.

Hospitality Industry: Coastal Resort Group standardized vinyl tile installations across 22 properties. Maintenance reports indicate 76% decrease in replacement costs compared to previous mineral fiber installations. The hydrophobic properties proved crucial in pool areas and spa facilities.

Healthcare Facilities: Regional Medical Center's emergency department renovation used custom antimicrobial tiles in bulk quantities. Infection control teams measured 55% reduction in surface pathogens compared to traditional ceilings. The moisture-resistant properties handled increased disinfection protocols without degradation.

These implementations demonstrate that economical solutions don't compromise functionality. The Jefferson County project achieved LEED Silver certification despite prioritizing budget tiles - proving that specification alignment matters more than premium pricing. Importantly, installation efficiency improved across cases - standardized bulk tiles reduced labor hours by 22% on average due to consistent sizing and simplified handling.

Strategic Sourcing for Quality 2x4 Drop Ceiling Tiles Cheap

Procurement specialists have developed proven strategies for maximizing value in bulk tile purchasing. Timing orders during construction industry slow periods (typically Q1) yields additional 8-12% savings through manufacturer incentives. Regional distributor partnerships offer advantages - the 2023 National Contractors Survey revealed direct mill purchases average 11% savings but require 30-day lead times, while distributors provide faster access at moderate premium.

Quantity thresholds remain critical: The price inflection points emerge at 500, 1,000 and 5,000 tile quantities. Purchasing just above these thresholds (e.g., 525 instead of 500) often yields identical pricing while accommodating waste factors. Standard recommendation includes ordering 7-9% overage to account for cutting waste and future replacements - a strategy that reduces replacement costs by eliminating minimum order fees for small quantities.

Importantly, verify certifications beyond basic fire ratings. Look for CRRC (Cool Roof Rating Council) certifications where energy efficiency matters, and NSF/ANSI 332 for healthcare applications. Sample testing provides additional security - legitimate manufacturers typically provide complimentary samples with same-week shipping. Final verification should include checking batch consistency across samples to ensure color match continuity in large installations.

(cheap ceiling tiles 2x4 in bulk)

FAQS on cheap ceiling tiles 2x4 in bulk

Q: Where can I buy cheap 2x4 ceiling tiles in bulk?

A: You can purchase cheap 2x4 ceiling tiles in bulk from major home improvement retailers like Home Depot or Lowe’s. Online marketplaces such as Amazon and eBay also offer discounted bulk pricing with various styles and finishes. Check their clearance sections for budget-friendly options.

Q: Why choose 2x4 ceiling tiles for cost savings?

A: 2x4 ceiling tiles are cheap because they're standardized, mass-produced, and minimize material waste. Their modular design allows quick installations, reducing labor costs significantly. Bulk discounts further drive down the price per tile for renovations.

Q: How much do drop ceiling tiles 2x4 cost in bulk?

A: Bulk 2x4 drop ceiling tiles start at $0.50 per tile for basic mineral fiber panels. Larger orders (250+ tiles) often reduce costs to $0.30–$0.40 per tile. Premium styles like tin or wood-look remain budget-friendly at $1–$2 per tile wholesale.

Q: Are cheap 2x4 ceiling tiles durable?

A: Yes, affordable 2x4 tiles use sturdy mineral fiber or PVC that resists sagging and moisture. While less dense than premium tiles, they meet fire-safety codes and typically last 10–15 years. Acoustic options also provide sound absorption for added value.

Q: What’s the cheapest way to install 2x4 drop ceiling tiles?

A: Combine bulk 2x4 tiles with inexpensive grid systems to save costs. Self-installation avoids labor fees—simply snap tiles into a suspended metal frame. Opt for lightweight panels to simplify handling and reduce support structure expenses.

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025