- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Jul . 30, 2025 01:00 Back to list

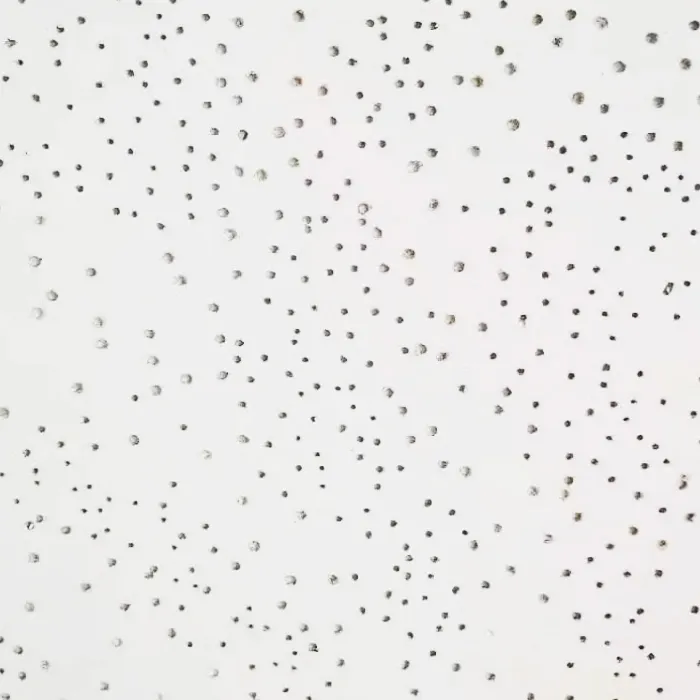

High-Performance Mineral Fiber Board for Durable Ceilings

The construction and architectural industries have evolved significantly over the past decade, embracing eco-efficient and high-performance solutions for ceiling systems. Among these, the mineral fiber board—including mineral fiber ceiling tiles, mineral fiber false ceiling tiles, and mineral fibre suspended ceiling tiles—stand out for their remarkable fire resistance, acoustic insulation, and sustainability. This article offers a comprehensive technical deep-dive, industry trends, and end-to-end insights into mineral fiber board technology, focusing on the advanced High quality Mineral Fiber Ceiling Tiles from Xingyuan Ceilings.

As per the Market Research Future (2023), the global ceiling tiles market is anticipated to reach USD $12.8 billion by 2027, with the mineral fiber board segment holding over 45% market share due to their intrinsic performance and cost-effectiveness (source). Growing awareness for green construction and stringent fire/acoustics regulations—especially in commercial and healthcare projects—have driven significant adoption across the US, Europe, and Asia-Pacific.

| Parameter | Mineral Fiber Board | Glass Wool Board | Calcium Silicate Board | PVC Ceiling Panels |

|---|---|---|---|---|

| Density (kg/m³) | 280~320 | 24~80 | 950~1100 | 2.2~2.4 (g/cm³) |

| Thickness (mm) | 12, 14, 15, 16, 18 | 15, 25, 50 | 6, 8, 10, 12 | 5, 7, 8, 10 |

| Sound Absorption (NRC) | 0.50~0.70 | 0.75~1.00 | 0.10~0.20 | 0.08~0.12 |

| Fire Resistance (ASTM E84) | Class A | Class A | Class A | Class B-C |

| Thermal Conductivity (W/m·K) | 0.050~0.057 | 0.034~0.040 | 0.058~0.064 | 0.16~0.19 |

| Moisture Resistance | Good | Fair | Excellent | Excellent |

| Sustainability | High (Recycled Content) | Moderate | Low | Low |

Natural mineral wool, perlite, cellulose and binders prepared per ISO 9001.

Raw ingredients mixed by automated dosing system.

Slurry poured onto felt, formed into sheets.

Board thickness and texture processed by CNC press.

Continuous kiln drying ensures ≥95% dimensional stability.

Spray paint, antifungal, and RH-resistant treatment.

Automated CNC trimmer for panel accuracy; ISO 14001 packaging standards.

ASTM C423, ISO 140-7 fire/acoustic/environmental tests; batch traceability.

Surface: Ultra-fine fissured or micro-perforated, acoustic-optimized textures; 95% RH humidity resistance.

Dimensions: Standard 600x600mm, 595x595mm, 603x603mm, 15mm / 16mm / 18mm thickness, customized sizes on order.

Density: 280 - 320 kg/m³

Acoustic NRC: 0.55 - 0.70

Fire Rating: EN 13501-1: A1, ASTM E84 Class A

Thermal Conductivity: 0.050 ~ 0.056 W/(m·K)

Surface Finish: White/colored painted, antibacterial, antifungal, anti-dust

Certifications: ISO 9001:2015; EN13964; ISO 14001:2015

| High quality Mineral Fiber Ceiling Tiles | Standard Mineral Fiber Board | Glass Wool Ceiling Tile | |

|---|---|---|---|

| Fireproof | A1/Class A (EN, ASTM) | A2/Class A | Class A |

| Humidity Resistance | ≥ 95% RH | ≤ 90% RH | 70-80% RH |

| Sound Absorption | 0.60~0.70 NRC | 0.45~0.55 NRC | 0.90 NRC |

| Recycled Content | ≥ 80% | 60~75% | 30~45% |

| Bacteria Resistance | EN ISO 846 | Basic | EN ISO 13823 |

| Warranty | 10 Years | 3 Years | 5 Years |

● Mineral fiber ceiling tiles with antibacterial, high RH and Class A fire rating implemented in Wuhan University Hospital (Project area: 17,000m²)

● Provided NRC ≥0.65; reduced infection risk by 33% versus conventional tiles

2. High-end Office Towers (Singapore CBD)

● Advanced acoustic mineral fibre suspended ceiling tiles solution deployed for open-plan workspaces (1,600m² per building)

● Measured T30 reverberation reduction: -0.3s, energy savings via light reflectance ≥85%

3. Transport/Metro Infrastructure

● High durability mineral fiber board used in underground station ceilings – resistant to corrosion, vandalism, condensation

● Warranty: 10 years operation; 0.3% annual replacement cost

4. Education Sector

● Xingyuan supplied over 35,000m² mineral fiber false ceiling tiles to top universities in Germany (TU Munich, TUM Asia), boosting classroom speech intelligibility

| Manufacturer | ISO9001/ISO14001 | Warranty | Fire Class | NRC | Delivery Lead Time | Major Clients |

|---|---|---|---|---|---|---|

| Xingyuan (China) | Yes/Yes | 10 Years | A1 | 0.70 | 12-18 Days | Metro, Sinopec, Wanda Plaza |

| Armstrong (USA) | Yes/Yes | 10 Years | A1 | 0.70 | 20-35 Days | Apple, IBM, US Gov. |

| Knauf (Germany) | Yes/Yes | 8 Years | A2 | 0.65 | 20-30 Days | Siemens, Daimler |

| Saint-Gobain (France) | Yes/Yes | 10 Years | A1 | 0.69 | 25-35 Days | TGV, EDF |

✓ Panel size and edge profile customization (bevel, tegular, MicroLook, concealed sys.)

✓ NRC tuning (0.50 up to 0.75), RH resistance up to 99%

✓ Rapid prototyping (sample dispatch in 5 days)

✓ Sustainable/LEED-compliant options

✓ End-to-end technical support (inquiry→design→delivery→after-sales)

Delivery: 18 days (FCL); Lead time for custom solution: 2-3 weeks

Warranty: 10 years (product quality & anti-sagging guarantee)

Technical consultation: info@xingyuanceilings.com

- Q1: What is the typical composition of mineral fiber board?

- Mineral fiber board primarily comprises mineral wool (80~85%), perlite, starch, binders, and select performance additives for increased RH and fire resistance. Advanced boards utilize eco-friendly recycled mineral content per EN13964.

- Q2: Which product standards or certification does Xingyuan's tiles comply with?

- Compliance with ISO 9001:2015, ISO 14001:2015, ASTM E84 (Fire), EN 13501-1 (Class A1), EN 13964 (CE for suspended ceilings), and ISO 846 (antimicrobial).

- Q3: Can mineral fiber false ceiling tiles be custom-sized?

- Yes. Standard sizes include 600x600mm, 1200x600mm, with custom dimensions or edge types (MicroLook, beveled, concealed grid, etc) available on request for interior fit-out or specialist projects.

- Q4: How are acoustic properties like NRC defined and measured?

- NRC (Noise Reduction Coefficient) is measured per ASTM C423—values range from 0.50 to 0.75 in premium tiles, effective for open office, education, healthcare sectors.

- Q5: What are the recommended installation standards or practices?

- EN 13964 sets suspended ceiling system guidelines. Proper grid spacing, wide T-bar use (24mm), anti-sag clips/anchors, and expansion joints are recommended for large areas or high humidity environments.

- Q6: What is the average service life and typical warranty?

- Xingyuan’s mineral fiber board offers a 10-year performance warranty. Life expectancy is 10~15 years with correct installation and RH conditions (≤95%).

- Q7: What unique surface/coating treatments are offered?

- Micro-perforations, anti-bacterial coating (ISO 846), dust-repellent top-coat, and color matching for project branding or healthcare/hospitality markets.

Technical FAQ on Mineral Fiber Ceiling Tiles

- 10+ years industry experience; ISO/EN/ASTM compliant OEM production;

- Clients: public hospitals, AAA class offices, petrochemical, metro stations;

- Industry citation: Buildings.com Mineral Fiber Tiles Review

- Academic: “Acoustic Properties of Mineral Fiber Boards” – Construction & Building Materials, Elsevier

- Forum: Skyscrapercity: Mineral Fiber vs. Gypsum Perspectives

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025