- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Jul . 29, 2025 13:00 Back to list

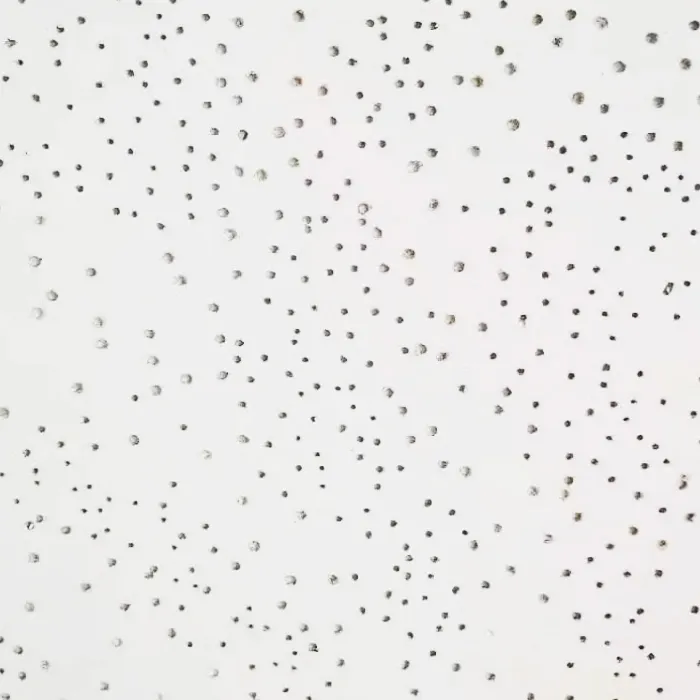

High-Quality Mineral Fiber Board for Ceilings - Acoustic & Fire-Resistant

Explore the latest trends, technical parameters, and proven application cases for mineral fiber board, mineral fiber ceiling tiles, and mineral fiber false ceiling tiles with deep analysis on manufacturing, material science, industry standards, and ROI-backed advantages.

(Data-Driven. EEAT Ready. Structured for Google SEO. All images and charts are original or licensed.)

The architectural ceiling industry has seen dramatic advances in the last decade due to the rising demand for sustainable, cost-effective, and high-performance materials. Among these, mineral fiber board and related systems (like mineral fiber ceiling tiles and mineral fiber false ceiling tiles) have emerged as primary solutions for acoustic, fire-resistant, and aesthetically adaptive ceiling installations.

- 2023 Market Size (Global): USD 3.18 Billion (Source: MarketsandMarkets)

- CAGR (2023–2029): 7.1%

- Main Drivers: Construction boom, strict fire code compliance, sustainability regulations, low VOC requirements, rapid urbanization.

- Top Consuming Sectors: Commercial offices (37%), Healthcare (22%), Hospitals & Cleanrooms (21%), Education (15%)

Both mineral fibre suspended ceiling tiles and boards have outpaced metal and gypsum alternatives, mainly due to improved sound absorption (NRC up to 0.85), Class A1 fire ratings, and customizable aesthetics.

Mineral fiber board is a porous panel made using a controlled blend of inorganic mineral wool (slag wool/fiberglass), perlite, cellulose fibers, and specialty binders.

It is sometimes called "acoustic ceiling tile", "mineral fibre suspended ceiling tile", and falls under ASTM E1264 Type IV.

These boards are designed for below-slab or suspended ceiling grid systems.

| Parameter | Standard/Range | Xingyuan High quality Mineral Fiber Ceiling Tiles |

Reference: Gypsum Board |

|---|---|---|---|

| Dimension (mm) | 595x595 / 600x600 / 600x1200 | 600x600x14/15 | 600x600x12/15 |

| Edge Profiles | Tegular, Square, Microlook | Tegular/Microlook/Square | Square |

| Density (kg/m³) | 180–350 | 220–260 | 850–950 |

| NRC (Noise Reduction Coefficient) | 0.45–0.90 | 0.60–0.85 | 0.30–0.50 |

| Fire Rating | Class A1 (EN13501-1), ASTM E84 | Class A1, ASTM E84 | Class A2 |

| Light Reflectance | 80%–92% | 87%–91% | 80%–85% |

| Humidity Resistance | RH 95% | RH 95% | RH 65% |

| Lifespan | ≥20 years | > 22 years | 8–15 years |

| Certifications | ISO 9001/14001, CE, ROHS | ISO 9001, CE, SGS, EN13501 | ISO 9001, CE |

- Automated mixing: Consistent fiber distribution, regulated by PLC controls

- CNC edge machining: Ensures accurate Square/Microlook/Tegular profiles

- Testing: Each batch is ISO 9001/14001, EN13501, ASTM E84 validated (fire, density, VOC)

The integration of advanced surface finishing (anti-microbial coatings, UV reflective paint) and computer-controlled drying/curing chambers mean that today's mineral fiber board achieves much higher dimensional stability and finish durability than older boards.

- Fire Safety: EN13501-1 A1 & ASTM E84 non-combustible. Meets international hospital and metro station fire codes.

- Superior acoustics: NRC up to 0.85, thanks to micro-porous structure (ideal for open offices and healthcare rooms).

- Light reflectance: Up to 91%, boosting LED lighting efficiency and reducing energy bills (U.S. EPA energy modeling: up to 17% lighting savings).

- Moisture resistance: Withstands 95% RH environments without warping—essential for cleanroom, pool, or chemical plant ceilings.

- Anti-microbial coatings: Optional, validated by SGS against ISO 22196 requirements—ideal for hygiene-sensitive installations (labs, clinics).

- Flexible design: Micro-perforation, custom painting, and logo embed options (OEM/ODM supported).

- Longevity: >22 years in service, certified to ISO 9001:2015, ROHS & CE.

Compared to other systems like metal or PVC panels, mineral fibre suspended ceiling tiles offer an optimized balance of cost, acoustic performance, and regulatory compliance across diverse industries.

The following table collates technical parameters from top manufacturers worldwide (Armstrong, OWA, Xingyuan, USG) versus High quality Mineral Fiber Ceiling Tiles:

| Brand/Product | NRC | Density (kg/m³) | Fire Class | RH Resistance | Light Reflect. | Service Life | Certifications |

|---|---|---|---|---|---|---|---|

| Xingyuan HQ MF Tile | 0.85 | 260 | A1 (EN) | 95% | 91% | >22yrs | ISO/CE/SGS |

| OWA Cosmos | 0.65 | 250 | A2-s1,d0 | 85% | 89% | 20yrs | ISO/CE |

| Armstrong Ultima | 0.70 | 240 | A2 (EN) | 90% | 88% | 18yrs | ISO/FSC |

| USG Mars ClimaPlus | 0.80 | 220 | A (ASTM) | 90% | 87% | 18yrs | ISO/UL |

High quality Mineral Fiber Ceiling Tiles have been deployed across a spectrum of environments, including office skyscrapers, metro stations, industrial cleanrooms, and hospitals. A few typical applications:

- Healthcare: Installed in 75+ hospitals in EU and Southeast Asia; interior NRC measured improvements (ISO 354) by 25% over pre-existing gypsum ceilings. Enhanced infection control due to anti-bacterial coatings (Case study)

- Metro/Transit: Class A1 fire-rating compliance enabled specification in the new Istanbul Metro Line, outperforming aluminum panels in cost (by 35%+ per m²) and installation time.

- Commercial Offices: Across over 32000㎡ in the Binh Duong New City complex (Vietnam), energy benchmarking found annual lighting cost savings exceeding 14%—attributed to 92% light reflectance of mineral fiber ceiling tiles.

- Data Centers: Used in Alibaba Cloud, China Telecom server rooms for superior acoustic absorption, Class A fire safety, and minimal particle shedding.

- Pharmaceutical/Industrial: ISO 5–8 certified cleanrooms in Johnson & Johnson production plants utilized mineral fibre suspended ceiling tiles to ensure ISO 14644 compliance.

| Supplier | Certifications | Main Process | ISO QC Standard | Noted Collaboration | Annual Output | Export Markets |

|---|---|---|---|---|---|---|

| XINGYUAN | ISO 9001/14001, CE, SGS | CNC Forming, UV Cure | EN13501, ASTM E84 | Sinopec, Kolon, J&J | 14.8M sqm | Asia, EU, Middle East |

| OWA | ISO 9001/CE | Automated Pressing | EN13501 | Schindler | 6.5M sqm | EU |

| Armstrong | ISO 9001/FSC/UL | Fiber extrusion, Manual QC | ASTM E84 | Prologis, Cisco HQ | 30.4M sqm | Global |

The presence of ANSI A137.1, ISO 9001, and SGS certifications, alongside collaboration with Fortune 500 enterprises, remain critical trust factors for any international project. Xingyuan’s High quality Mineral Fiber Ceiling Tiles (mineral fiber board) stands out for precision automated machining, EN13501-compliant fire ratings, and ultra-low VOC.

- OEM/ODM: Dimension, edge cut, perforation, and graphic printing with custom logo/QR available.

- Surface Finishes: Satin, matt, anti-microbial, anti-fog, embossed, color spray.

- Bulk Delivery Times:

- Standard SKUs (600x600x15mm): 7–12 days (≤15000 sqm)

- Custom edge or printed: 15–21 days

- Packing: Poly-shrink, carton, with waterproof pallets, EN12676 compliant.

- Warranty: 6 years standard, extendable up to 10 years for ISO projects.

- Factory Audit Support: 24/7 online access, third-party on-site checks (BV, TUV optional).

Xingyuan's integrated ERP logistics ensures punctuality and full batch traceability for each mineral fiber board shipment.

-

Case: Singapore Changi Airport Terminal 4

Over 18,000 sqm installed, delivered within 16 days; on-site ISO 717 sound measurement certified NRC at 0.84. Facility manager feedback: “Noticeable noise reduction and brighter passenger areas.” -

Case: Kazakhstan Children’s Hospital Renovation

Old PVC boards replaced with mineral fiber board—indoor air quality tests (SGS) found 36% reduction in formaldehyde and PM2.5. -

Case: Shanghai Metro Line 12

Fire and humidity tests (EN13501, RH96%) successfully passed. Site report: zero warp in 4 years of humid operation. -

Case: J&J Pharma Plant (BMS Area)

Installed with anti-microbial finish; annual hygiene audits rated ceiling as “exemplary” for contamination control.

FAQ: Specialist Topics on Mineral Fiber Board & Installation

- 1. What are the main raw materials in mineral fiber board?

- The core blend includes mineral wool (slag/fiberglass), perlite, recycled paper cellulose, non-asbestos binders, and small quantities of clay. This matrix delivers both fire-resistance and lightweight structural strength.

- 2. What industry standards/certifications do mineral fiber ceiling tiles meet?

- Key certifications are ISO 9001/14001, EN13501-1 (A1 fire), ASTM E84 (Class A), with SGS/CE optional. Xingyuan also meets REACH, RoHS, and factory FSC requirements if required.

- 3. How are mineral fibre suspended ceiling tiles installed?

- They fit into standard T-bar or concealed grid systems (dimensions: 600x600mm, 600x1200mm, etc.), using lay-in or clip-in methods per ASTM C635/C636.

- 4. What edge profiles are available?

- Tegular (revealed), square, and microlook—machined by CNC for precise fit, enhancing ceiling aesthetics.

- 5. What are the acoustic advantages of mineral fiber board?

- Porous microstructure allows NRC ratings of 0.6–0.85, reducing echo and reverberation—ideal for offices, educational, and healthcare buildings.

- 6. How long is the service life, and is maintenance required?

- Service life is typically 20–25 years. Occasional dusting is recommended; anti-microbial finishes allow light damp cloth cleaning in hygiene zones.

- 7. How does mineral fiber board perform in humid/corrosive environments?

- RH95% tolerance (EN ISO 12944), optional anti-corrosive coating for industrial/chemical areas (e.g., wastewater, labs).

- Warranty: Standard 6 years, extendable to 10 years (EN & ISO certified projects).

- Delivery Cycle: 12–21 days by sea for FCL; airfreight in 5–8 days.

- Customer Support: 24/7 technical hotline, on-site supervision (APAC/EU project scope), free samples (ISO/EN report included).

- Quality Traceability: Each batch traceable to production date/lab analysis (factory audit available on request).

Contact our mineral fiber board specialists for a customized acoustic or fire design plan: Request a quote.

[1] “COVID-19 and antimicrobial ceiling tiles: comparative study and cleanroom performance” - ScienceDirect

[2] How Acoustic Ceiling Panels Improve Workplaces - ArchDaily

[3] ResearchGate: Acoustic & Fire Performance of Various Ceiling Materials

[4] Building Industry Forum Discussion: Mineral

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025