- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Jun . 09, 2025 03:31 Back to list

Premium PVC Laminated Gypsum Boards - Best Prices & Designs

- Technical Advantages of PVC Laminated Gypsum Boards

- Understanding PVC Laminated Gypsum Board Price Factors

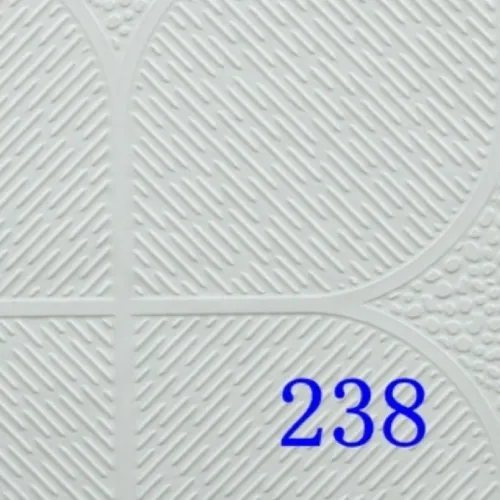

- Design Innovations in PVC Laminated Gypsum Ceiling Tiles

- Comparative Analysis of PVC Laminated Gypsum Board Manufacturers

- Tailored Solutions for PVC Laminated Gypsum Applications

- Installation Considerations for Professional Results

- Real-World Applications of PVC Laminated Gypsum Ceiling Systems

(laminated gypsum)

Technical Advantages of PVC Laminated Gypsum Boards

Modern construction increasingly adopts laminated gypsum

solutions due to their performance characteristics. The PVC fusion process creates a molecular bond that transforms gypsum into a durable surface resistant to moisture penetration. Laboratory tests demonstrate 96-98% humidity resistance, significantly outperforming standard gypsum panels. This hydrophobic quality prevents microbial growth and material degradation in challenging environments.

Structural integrity remains uncompromised despite the protective layer. The core gypsum maintains its industry-standard fire rating of 60-120 minutes depending on thickness, while the PVC overlay contributes additional flame-retardant properties. Thermal stability testing shows minimal expansion/contraction (±0.07%) between -20°C and 50°C. Industry professionals value the 400-800 PSI impact resistance – approximately triple that of conventional gypsum – reducing damage during installation and occupancy.

Maintenance requirements decrease substantially with this surface technology. The non-porous finish permits thorough cleaning with industrial-grade disinfectants without material degradation. Accelerated aging simulations indicate surface integrity maintenance beyond 15 years of commercial use.

Understanding PVC Laminated Gypsum Board Price Factors

Material costs fluctuate based on composition quality and regional availability. Premium-grade boards incorporating UV-stabilized polymers and anti-fungal additives command 20-30% higher prices than entry-level products. Standard 12mm thickness typically ranges between $3.50-$5.75 per square foot in North American markets.

Production complexity significantly influences pricing structures. Boards featuring specialized edge treatments (tapered, bevelled, or reinforced) increase manufacturing costs by 12-18%. Custom coloration requires production line adjustments adding 8-15% to base prices. Manufacturers offering integrated acoustic properties (NRC 0.5-0.7) price these solutions 15-22% above standard laminates.

Logistical considerations contribute to regional price variations. Imported panels carry 18-25% tariff implications in certain markets. Bulk purchasing (500+ sheets) typically delivers 10-15% economies of scale. Professional installation constitutes 30-45% of total project expenditure when accounting for specialized framing requirements.

Design Innovations in PVC Laminated Gypsum Ceiling Tiles

Aesthetic flexibility drives architectural adoption of laminated solutions. Contemporary printing technology enables photorealistic reproductions including natural materials like marble, timber, and brushed metals with 98% visual accuracy. Reflective index options now range from matte (3-5 gloss units) to high-gloss (85+ gloss units) finishes.

Three-dimensional treatments create unprecedented ceiling dynamics. Embossed geometric patterns achieve 6-18mm relief depths while maintaining structural integrity. Integrated indirect lighting solutions utilize translucent laminates with 40-60% light transmission. Colorfastness testing confirms Delta-E values below 1.0 after 5,000 hours of UV exposure, ensuring long-term visual consistency.

Modular design systems support complex configurations. Standard 600x600mm and 1200x600mm formats enable endless combination possibilities. Edge detailing innovations include:

- Magnetic perimeter systems for tool-free access

- Micro-beveled transitions creating shadow-line effects

- Integrated air diffusion patterns maintaining HVAC efficiency

| Manufacturer | Density (kg/m³) | Moisture Resistance | Fire Rating | Price Range ($/m²) | Warranty Period |

|---|---|---|---|---|---|

| EuroGypsum ProSeries | 725 | 96% RH stable | Class A/1-hr | 12.40 - 16.80 | 15 years |

| DuraLam GypsumTech | 690 | 92% RH stable | Class A/45-min | 9.75 - 14.20 | 10 years |

| ShieldLam Industrial | 755 | 98% RH stable | Class A/2-hr | 14.90 - 21.30 | 20 years |

| ProLam EcoSolutions | 650 | 89% RH stable | Class B/30-min | 7.99 - 11.50 | 7 years |

Tailored Solutions for PVC Laminated Gypsum Applications

Healthcare facilities necessitate specialized formulations meeting hygienic compliance. Antimicrobial-infused laminates with ISO 22196 certification inhibit pathogen growth. Impact-resistant treatments for behavioral health units withstand 18 joules of force without surface fracturing. Radiographic imaging rooms incorporate barium-enriched cores providing 0.8mm lead equivalency.

Food production environments utilize USDA-compliant non-porous surfaces with NSF/ANSI 51 certification. Enhanced chemical resistance withstands daily sanitization using quaternary ammonium compounds. Processing facilities implement anti-static formulations preventing particulate adhesion in critical zones.

High-traffic public spaces benefit from scratch-resistant nanotechnology coatings maintaining appearance despite repeated contact. Stadium concourses implement rubberized backing layers mitigating vibration transmission. Transportation terminals install low-smoke-density cores meeting EN 45545-2 fire safety standards.

Installation Considerations for Professional Results

Substrate preparation ensures optimal performance. Framing alignment must maintain strict 3mm/1m tolerance to prevent stress fracturing. Panel acclimatization requires 48-hour conditioning at installation-site humidity levels. Expansion gaps (minimum 8mm perimeter) accommodate material movement without visible joint separation.

Cutting techniques vary by installation complexity. Computerized numerical control (CNC) routers deliver clean openings for integrated lighting/ventilation. For on-site modifications:

- Carbide-tipped blades prevent edge chipping

- 15° bevel cuts ensure seamless transitions

- Dedicated laminating tape protects exposed edges

Mechanical fastening systems require precision. Screw placement should maintain 15mm clearance from panel edges. Fastener heads must achieve consistent 0.5mm depression for proper concealment. Adhesive-assisted installation utilizes urethane formulations with 300 PSI bonding strength.

Real-World Applications of PVC Laminated Gypsum Ceiling Systems

Commercial kitchen ceilings demonstrate remarkable durability in extreme conditions. Major restaurant chains report 60% reduced maintenance costs post-conversion to laminated gypsum. The impermeable surface withstands daily grease-laden steam exposure without degradation. Temperature cycling resistance prevents sagging even directly above industrial cooking equipment reaching 65°C.

Public aquatic facilities leverage moisture-resistant properties effectively. Indoor swimming complexes document significant advantages including:

- Elimination of condensation dripping

- Corrosion-free suspension systems

- Zero chlorine-induced surface erosion after 8+ years

Specialized manufacturing plants achieve simultaneous compliance requirements. Semi-conductor cleanrooms maintain ISO Class 5 standards with anti-static ceiling solutions. Pharmaceutical facilities meet FDA cGMP regulations with non-shedding surfaces. Automotive paint booths benefit from chemical-resistant formulations preventing overspray adhesion.

Retail environments employ laminated gypsum to create branded architectural experiences. Flagship stores implement custom printed ceilings matching corporate identities precisely. The lightweight nature allows creation of complex volumetric ceilings without structural reinforcement – one luxury boutique suspended a 3-ton wave formation using specialized aluminum framing.

(laminated gypsum)

FAQS on laminated gypsum

Q: What factors affect pvc laminated gypsum board price?

A: Pricing depends on board thickness, surface finish quality, and supplier location. Additional costs may include custom designs or bulk order discounts. Market demand fluctuations also influence final costs.

Q: Are there moisture-resistant options for pvc laminated gypsum ceiling tiles?

A: Yes, PVC laminated gypsum ceiling tiles feature waterproof coatings that repel humidity. This makes them suitable for kitchens and bathrooms where they resist warping and mold growth. Ensure joints are properly sealed during installation for maximum protection.

Q: Where can pvc laminated gypsum ceilings be installed?

A: These ceilings work well in commercial spaces like offices, hospitals, and retail stores. They're equally suitable for residential areas including living rooms and hallways due to their fire resistance and easy maintenance. Avoid extreme heat environments above 50°C.

Q: What design options exist for pvc laminated gypsum ceiling tiles?

A: Choices include wood grain, marble textures, solid colors, and geometric patterns. Modern digital printing enables photographic designs and corporate branding integration. Tile sizes range from standard 60x60cm to custom dimensions.

Q: How does pvc lamination enhance gypsum board performance?

A: The PVC film layer dramatically improves moisture resistance compared to standard boards. It creates a wipe-clean surface that resists stains, scratches, and daily wear. This also allows for seamless appearance without visible joints when installed professionally.

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025