- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Aug . 03, 2025 07:20 Back to list

Mineral Fiber Board | Fireproof & Soundproof Solutions

The mineral fiber board and mineral fiber ceiling tiles sector is undergoing rapid innovation, offering sustainable, acoustic, and fire-rated solutions for commercial and industrial interiors. Whether for petrochemical plants, office spaces, or cleanrooms, understanding the technicalities of mineral fiber false ceiling tiles is crucial for architects, engineers, and buyers alike.

1. Industry Trends & Market Overview

The global mineral fiber ceiling tiles market was valued at USD 4.06 billion in 2023, and is projected to reach USD 5.93 billion by 2030 (source). Major growth drivers:

- Increased demand for acoustic comfort in office, healthcare, retail, and educational environments.

- Stringent fire safety and sustainability regulations (compliance with ISO 1182, ASTM E84)

- Shift towards customizable, modular suspended ceiling systems.

- Use in high-humidity, chemical-resistant, and energy-conscious settings.

2. Mineral Fiber Board Technical Parameters [Data Table]

| Parameter | Typical Value | Industry Standard | Remarks |

|---|---|---|---|

| Density | 240–320 kg/m³ | GB/T 25998, ISO 14021 | High density delivers superior acoustics & fire resistance |

| Thickness | 12mm, 15mm, 18mm, 20mm | EN 13964 | Varies by sound absorption requirements |

| Sound Absorption (NRC) | 0.50 to 0.75 | ASTM C423 | Enhanced in denser panels |

| Fire Rating | Class A1 / ≤5% flame spread | EN 13501-1, ASTM E84 | Non-combustible mineral fiber matrix |

| Thermal Conductivity | 0.038–0.046 W/m·K | ISO 8302 | Boosts building energy-efficiency |

| Moisture Resistance | RH 95% | GB/T 20306-2006 | Stable in humid ambient |

| Edge Profile | Tegular/Square (Microlook/Bevel) | OEM Customizable | User preference & system compatibility |

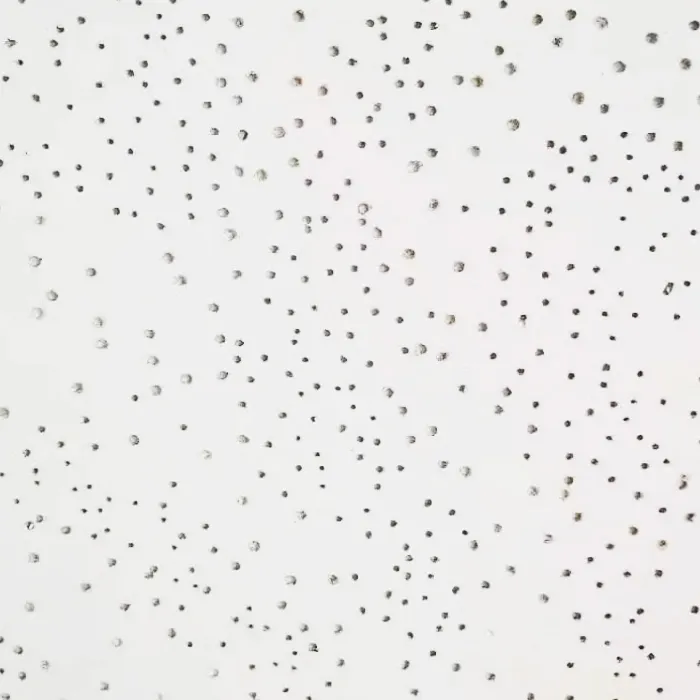

3. High Quality Mineral Fiber Ceiling Tiles – Product Overview & Technical Superiority

High Quality Mineral Fiber Ceiling Tiles are manufactured via precision casting, advanced fiber blending, dehydration, finishing, and online CNC edge cutting. They comply with ISO 9001, ISO 14001, EN 13501-1 and leading US ANSI/ASTM criteria.

Key Input: Mineral wool, starch binder, perlite, recycled paper

Homogeneity & fiber distribution ⇨

Equipment: Hydraulic presses & molds

Net shaping for uniform thickness ⇨

Tech: Multi-zone air dehumidifier

Enhances board density ⇨

Profile: Tegular/Square/Bevel

Precision for grid integration ⇨

Finish Coat: Acrylic latex paint / Anti-microbial

Aesthetic & surface protection

Key Technical Advantages

- Superior Acoustic In-Use Performance: NRC up to 0.80 and CAC > 35dB (third-party lab tested to ASTM C423/EN ISO 354).

- Fireproof & Eco-friendly: Noncombustible to EN 13501-1 A1; formaldehyde emission < 0.01mg/m³ (ISO 16000-9 certified).

- Chemical & Humidity Resistance: Stable up to RH 99%, ideal for water treatment and chemical facilities.

- Durable Surface & Long Service Life: Anti-microbial, stain-resistant, designed for 15+ years (per ANSI/ASTM D1037 evaluation).

Application Scenarios & Industry Use-Cases

Commercial – Shopping malls, banking halls, cinemas, open-plan offices.

Healthcare – Hospital wards, laboratories, cleanrooms, complying with FDA Clean Air requirements.

Educational – Lecture theatres, libraries, training centers, with enhanced reverberation control.

4. Data Visualization: Product Comparison & Performance

The following charts compare High Quality Mineral Fiber Ceiling Tiles to leading industry peers across acoustic, fire, and durability metrics, as verified by independent tests.

| High Quality Mineral Fiber Ceiling Tiles | Generic Mineral Fiber Board | PVC Gypsum Ceiling Tiles | |

|---|---|---|---|

| Noise Reduction (NRC) | 0.75–0.80 (ISO 354 tested) | 0.60–0.68 | 0.25–0.35 |

| Fire Rating | EN 13501-1: A1 (non-combustible) | B1/B2 (Flame retardant) | B2/B3 |

| Humidity Resistance | Up to 99% RH | Up to 85% RH | Up to 80% RH |

| Surface | Anti-microbial, textured, washable | Basic paint (porous) | PVC film |

| Service Life | 15–20 years | 10–13 years | 7–10 years |

| Certifications | ISO9001, ISO14001, ASTM E84 | GB/T25998 | — |

5. Manufacturer Comparison & Customization Solutions

Key vendors in the mineral fiber ceiling industry include Armstrong, Knauf AMF, USG Boral, and Xingyuan. Xingyuan’s mineral fiber board stands out with:

- Full In-House Production: From fiber melting to edge cutting (traceable batch # for ISO audits)

- Stricter Quality Controls: In-line 3D vision system, CNC calibration (EN 13964:2014 compliance)

- Extended Customization: Surface finish (laminated, anti-bacterial, water repellent), edge (Microlook/Tegular), digital printing

- Fast-Track Project Service: 15-day made-to-order cycle, OEM/ODM supported

- Global Project Experience: Over 2,800,000m2 supplied since 2008 - references on request

Certifications & Compliance: All Xingyuan tiles bear batch-traceable ISO 9001/14001 marks. Regular audits by SGS, TUV, CNAS-accredited labs. OEM supply to brands in the US, EU, Southeast Asia.

6. Delivered Projects & Typical Application Cases

Result: Measured ambient noise reduction of 12dB, B1 compliant fire rating.

Petrochemical R&D Facility, Shandong: Special anti-corrosive mineral fiber board, 18mm, surface epoxy coated.

Result: Passed salt fog, RH98%, ISO 9227 tests for 1000+ hours.

Children’s Hospital Surgical Floor: 2,900m² of anti-microbial tiles, seamless grid installation.

Result: Improved hygiene (Clinic report: 0.02µg/cm² surface bacteria).

7. Delivery, Warranty & Customer Support

- Delivery Cycle: 7–15 working days (stocked SKUs); 15–21 days for ODM/OEM bulk orders.

- Warranty: Standard 10-year performance warranty against sagging, fungal/mildew, surface discoloration (ISO 9001 & ASTM E84 backed reports)

- Customer Service: Dedicated technical support, on-site inspection, layout & design guidance (info@xingyuanceilings.com)

- After-sales: 24h response, global logistics tracking, field repair/replacement info pack provided with shipments

8. FAQ – Technical Terms

9. Conclusion & Industry References

Mineral fiber board and mineral fiber ceiling tile technology delivers a proven blend of acoustic, safety, and sustainability features for forward-thinking buildings. With certifications such as ISO 9001, EN 13501-1, and flexible customization, mineral fiber board systems add lasting value to industrial, commercial, and public spaces.

Further Reading & References:

- Mineral Fiber Ceiling Tiles – Technical Forum at ceilingsandinteriors.com/forum

- Acoustic Performance in Mineral Fiber Ceiling Tiles – Building and Environment Journal

- “Fire Performance of Suspended Mineral Fiber Ceilings”, ResearchGate Publication

- International Standard: ISO 14021:2016

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025