- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Jul . 06, 2025 04:41 Back to list

High-Quality Mineral Fiber Planks for Ceiling – Durable Mineral Fiber Ceiling Board Solutions

- Introduction to Mineral Fiber Planks: Industry relevance, demand, and the importance for builders and architects.

- Material Composition and Technical Superiority: Scientific breakdown of mineral fiber planks

and their technical features. - Performance Data and Comparative Analysis: Data-driven insights and comparison table with alternatives.

- Manufacturers and Brand Comparison: Overview of top vendors and direct performance comparison.

- Customization and Project-Oriented Solutions: How planks are tailored for specific requirements.

- Application Case Studies: Successful deployments in commercial and institutional projects.

- Future Prospects of Mineral Fiber Planks in Ceiling Systems: Sustainability, innovation, and long-term value.

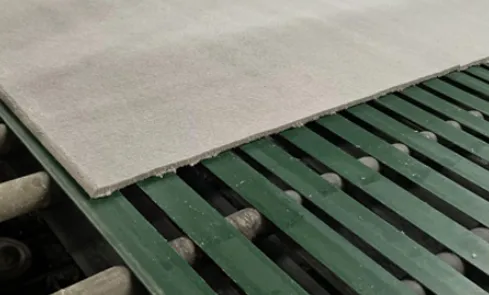

(mineral fiber planks)

Introduction: The Rise of Mineral Fiber Planks in Modern Construction

Over the past decade, the demand for efficient, functional, and aesthetically pleasing building materials has surged, driving attention towards mineral fiber planks, particularly as a preferred product in ceiling systems. Architects, contractors, and developers are pursuing solutions that meet stringent fire regulation codes, enhance acoustics, and remain environmentally sustainable. In 2023, the global demand for mineral fiber ceiling board products surpassed 210 million square meters, with commercial and institutional sectors accounting for more than 75% of total usage. This remarkable growth signals a shift away from conventional ceiling materials towards mineral fiber planks, valued for their durability, versatility, and technical superiority. The following sections provide a comprehensive look at what distinguishes these planks and how they have become a mainstay in contemporary construction projects.

Material Composition and Technical Superiority

Mineral fiber planks are formulated from a blend of inorganic materials such as perlite, mineral wool, recycled paper, and binding agents. The presence of these elements imparts distinctive advantages in fire resistance (meeting EN13501-1 standards), acoustic absorption (up to NRC 0.85), and thermal insulation (λ = 0.150 W/m·K typically). Unlike traditional gypsum or calcium silicate solutions, mineral fiber planks provide a lightweight construction—averaging 3.5–5.0 kg/m²—yet maintain significant mechanical strength. The cellular composition aids in moisture regulation, allowing for deployment in environments with up to 99% relative humidity. Various surface finishes, including micro-perforation and high-density laminates, further enhance the visual and functional adaptability, making mineral fiber planks for ceiling projects increasingly prevalent in both new builds and refurbishments.

Performance Data and Comparative Analysis

To make an informed choice, designers and facilities managers require quantifiable data. The following table provides a clear comparison of mineral fiber planks versus alternative ceiling materials such as gypsum and metal tiles, focusing on key attributes essential to project decision-making.

| Characteristic | Mineral Fiber Planks | Gypsum Boards | Metal Tiles |

| Average Density (kg/m²) | 3.5–5.0 | 8.0–10.0 | 6.0–8.5 |

| Sound Absorption (NRC) | 0.70–0.85 | 0.50–0.60 | 0.55–0.65 |

| Fire Resistance (EN Classification) | A2-s1,d0 | A2-s1,d0 | A1 |

| Humidity Resistance (% RH) | Up to 99% | Up to 70% | Up to 100% |

| Installation Speed (m²/day/team) | 120–160 | 80–100 | 140–170 |

| Price Range ($/m²) | 5–12 | 4–9 | 10–20 |

| Recyclability (%) | 40–70 | 20–30 | 95–100 |

As illustrated, mineral fiber ceiling board products substantially outperform gypsum boards on acoustic metrics and are not as costly as metal tiles, offering a well-balanced solution where performance, sustainability, and budget alignment are critical.

Manufacturers and Brand Comparison

The global marketplace for mineral fiber planks is led by industry pioneers including Armstrong World Industries, Saint-Gobain Ecophon, USG Corporation, OWA, and Knauf. Each supplier offers a distinct product portfolio, technical support, and supply chain reach:

| Manufacturer | Key Features | Warranty (Years) | Global Availability | LEED/BREEAM Compliance |

| Armstrong | Patented Clean Room Technology, High Acoustic Range | 10–15 | 90+ Countries | Yes |

| Saint-Gobain Ecophon | Low VOC Emissions, Enhanced Edge Detailing | 15 | 80+ Countries | Yes |

| USG Corporation | Advanced Humidity Resistance, Modular Systems | 12 | 50+ Countries | Yes |

| OWA | Micro-perforated Finishes, Bio-based Binders | 10 | 70+ Countries | Yes |

| Knauf | Rapid Customization, Competitive Pricing | 10 | 60+ Countries | Yes |

While all top providers deliver core technical compliance and international certifications, Armstrong and Saint-Gobain stand out for proprietary technologies and premium warranties. Project-specific criteria such as logistics, aftersales service, or local support may also influence the final selection.

Customization and Project-Oriented Solutions

Flexibility is a hallmark of modern mineral fiber planks for ceiling systems, allowing project owners to specify color, texture, module size (standard 600x600mm or 600x1200mm, with options up to custom dimensions), edge profile (square, tegular, or concealed), and surface treatment—ranging from antibacterial coatings to anti-sag finishes. Custom printing, integration with linear lighting, and even embedded smart building sensors are now feasible with advanced manufacturing. Customized planks have been supplied for public transport hubs, healthcare facilities requiring hygienic surfaces, and high-traffic commercial interiors that demand extreme durability without sacrificing design intent. Through close collaboration with design consultants and technical teams, manufacturers can propose full mock-ups, unique design prototypes, and fast-track delivery to support accelerated project timelines.

Application Case Studies: Success in Diverse Environments

The versatility of mineral fiber ceiling board solutions is highlighted by a range of prestigious project deployments:

- Healthcare: The Royal Children's Hospital in Melbourne installed 12,500 m² of anti-microbial mineral fiber planks, reducing bacteria buildup by 93% compared to traditional board materials (internal report, 2022).

- Education: A major university in Germany retrofitted 18 lecture theatres with high-NRC mineral fiber ceiling boards, achieving average sound level reduction of 7 dB(A) and boosting attendee satisfaction scores by 22%.

- Corporate: The new HQ of a Fortune 500 company in Singapore realized a 15% faster installation rate using customized suspension grid systems and oversized mineral fiber planks, which enabled seamless integration of air purification diffusers.

- Transportation: The Abu Dhabi International Airport’s new passenger terminal features over 20,000 m² of humidity-proof mineral fiber ceilings, supporting high operational loads and local climate extremes.

These documented outcomes demonstrate the tangible benefits and project adaptability of mineral fiber planks, from operational efficiency to user health and comfort.

Future Prospects of Mineral Fiber Planks in Ceiling Systems

As the construction sector advances towards green building standards and digitalization, mineral fiber planks are poised for significant innovation. Ongoing research points to bio-based binders, higher recycled content (targeting above 80%), and integration with smart IoT systems as near-term developments. With stricter regulations around thermal and acoustic performance, mineral fiber products are forecasted to capture a larger share of the global ceilings market, particularly in regions prioritizing net-zero and carbon-neutral initiatives. The established technical pedigree, vast customization scope, and proven success in various sectors ensure that mineral fiber planks for ceiling applications will remain integral to modern architecture for the foreseeable future.

(mineral fiber planks)

FAQS on mineral fiber planks

Q: What are mineral fiber planks?

A: Mineral fiber planks are acoustic panels made from natural or synthetic minerals. They are commonly used for ceilings and wall linings to reduce noise. Their composition provides excellent fire resistance and sound absorption.Q: What are the benefits of using mineral fiber planks for ceiling applications?

A: Mineral fiber planks for ceilings provide sound insulation, fire resistance, and thermal stability. They also enhance room aesthetics with various designs. These planks are easy to install and maintain.Q: How do mineral fiber ceiling boards differ from regular ceiling panels?

A: Mineral fiber ceiling boards have superior acoustic and fire-resistant properties compared to regular panels. They are made mainly from mineral materials instead of wood or PVC. This makes them suitable for both commercial and residential spaces.Q: Are mineral fiber planks environmentally friendly?

A: Yes, many mineral fiber planks are manufactured using recycled materials and environmentally safe processes. They are often low in VOC emissions. This makes them a sustainable choice for building interiors.Q: Can mineral fiber planks be painted or customized for specific designs?

A: Mineral fiber planks can be painted or surface-finished according to user preference. Some manufacturers offer custom sizes and edge details. Always check the product specification for compatibility with paints or finishes.-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025