- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Aug . 01, 2025 08:20 Back to list

Premium Ceiling T Grid Systems | Lightweight & Durable

Explore Ceilings t grid Suspended System full specs »

Industry Trends: The Evolving Ceiling t grid Market

- Grid ceiling materials moving toward lightweight galvanized steel, aluminum for corrosion resistance, and modularity.

- Integration with MEP (Mechanical, Electrical, Plumbing) and HVAC for cleaner installations.

- Attention to LEED/BREEAM certifications—demanding low-VOC finishes & recyclable components.

- Rapid growth in Ceiling t grid installation in data centers, cleanrooms, and transportation hubs.

Technical Parameters: Ceiling t grid Product Benchmark Table

| Parameter | Ceiling t grid (Standard) | Grid Ceiling Material | Cross Tee Ceiling | Gridstone Ceiling Tile Cost |

|---|---|---|---|---|

| Main Runner Size | 24 x 38 x 3600 mm | 24 x 32 x 3000 mm | 24 x 25 x 600 mm | 600 x 600 x 15 mm (for tiles) |

| Material | Galvanized Steel (HDG Z120) | Aluminum, Steel | Steel/Aluminum | Gypsum board, Polyvinyl* |

| Corrosion Protection | Epoxy/Polyester powder | Anodized/PVC coated | Galvanized/Anodized | Anti-fungal surface |

| Fire Resistance | ASTM E119/EN 1365 rating up to 1 hr | Non-combustible | Non-combustible | EN 13501 Euroclass A1 |

| Load Capacity | 12–16 kg/m2 | 10–13 kg/m2 | 6–8 kg/m2 | (N/A) |

| Drywall Ceiling Grid Price (USD) | 1.80/m | 2.40/m (aluminum) | 1.20/m | 2.00~4.50/PC (tile) |

| Relevant Standards | ISO 9001 / ASTM C635 / EN 13964 | ISO 9001 / ANSI A1355 | ASTM C635 | CE / SGS |

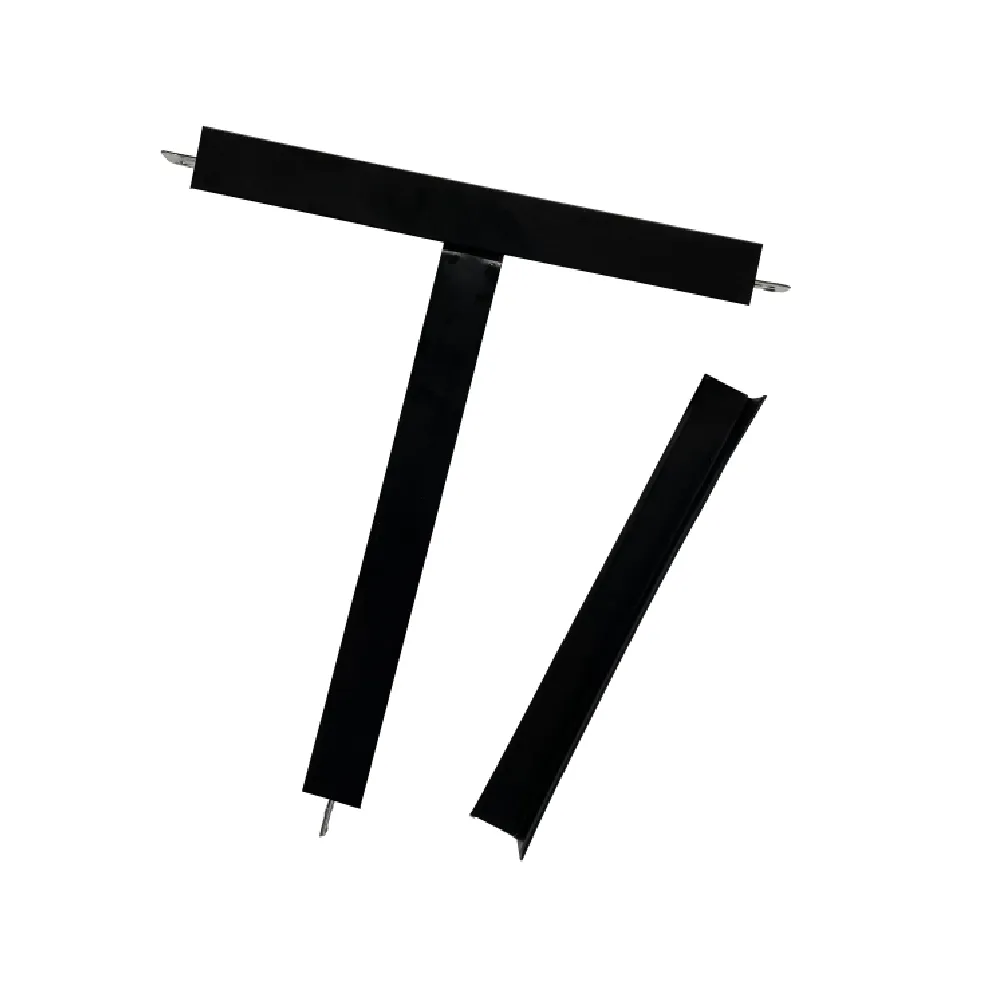

Product Spotlight: Ceilings t grid Suspended System

- Material: Hot-dipped galvanized steel (HDG Z140–Z180, thickness 0.27–0.40 mm)

- Surface: White powder coating, low-VOC, ≥ 1200 hour Salt Spray Resistance

- Sizes: Main T 24x38x3600mm, Cross T grid 24x25x1200/600mm, Wall Angle 24x24x3000mm

- Snap-in cross tee ceiling locking mechanism for fast installation

- Load bearing: up to 18 kg/m2

- Fire resist: ASTM E119/EN 1365, up to 1 hr. fire rating

- Certifications: ISO 9001, SGS, CE, TUV Rheinland

Manufacturing Process & Quality Control Flow

Preparation

Key Manufacturers: Global Comparison (2024)

| Brand | Core Segment | Certifications | Lead Time (Days) | Gridstone Ceiling Tile Cost (USD) | Warranty |

|---|---|---|---|---|---|

| Xingyuan Ceilings | Ceilings t grid Suspended System | ISO 9001, CE, ASTM | 11–18 | 2.20–3.50 | 10 Years |

| Armstrong World Industries | Grid & Tiles | LEED/Greenguard, CE | 15–25 | 3.00–4.80 | 5 Years |

| Knauf | Drywall grid, acoustic | ISO, DIN, CE | 17–24 | 2.70–3.90 | 7 Years |

| Saint-Gobain | Commercial grid | EN/ISO/CE/SGS | 14–21 | 3.10–5.20 | 8 Years |

Tailored Solutions & Custom Engineering

- Special grid profiles and colors (RAL/BS/Pantone)

- Antimicrobial powder coating for healthcare, food processing, pharmaceuticals

- Heavy-duty cross tee ceiling system for technical floors and MEP concealment

- Enhanced corrosion protection for chemical, petrochemical sectors

- Optimized grid modules for integration with fire/sprinkler/HVAC

Case Studies: Industry-specific Ceiling t grid Applications

- ✓ Grid system: Hot-dipped galvanized, with powder-epoxy surface, grid module 600x600 mm, used in control and server rooms.

- ✓ Result: Maintained corrosion-free performance for 20+ months in 85% RH & mild H2S exposure.

- Antibacterial coated cross tee ceiling grid installed in operating suites & sterile corridors.

- End-user feedback: “Easy to disinfect, robust connection between main/cross T bars, zero rust after repeated cleaning.”

- Aluminum grid ceiling material specified for ventilation shafts & platform lobbies.

- Excellent fire resistance and integration with sprinkler systems.

Expert Q&A: Suspended Ceiling t grid Systems

Q1. What are the main materials used in ceiling t grid manufacturing?

A: Predominantly hot-dipped galvanized steel (HDG Z140–Z180) for superior corrosion protection, plus aluminum for ultra-light, non-magnetic, or high-humidity environments. All materials comply with ISO 9001 traceability and EN 13964 mechanical standards.

Q2. What is the difference between a "cross tee ceiling" and a "main runner"?

A: The main runner (Main T) forms the primary longitudinal grid, typically 3.6m or 3.7m, with higher load bearing; the cross tee ceiling (Cross T) are shorter pieces (0.6/1.2m) that interlock perpendicularly, forming the tile substructure.

Q3. What coatings are available for enhanced grid corrosion resistance?

A: Epoxy and polyester powder coatings are standard, with additional options of PVDF/Lanthanum for chemical or outdoor exposure. Coating thickness is usually 70–120 μm, salt spray resistance ≥ 1200 hrs (EN ISO 9227:2017).

Q4. Are the grids certified for fire and safety requirements?

A: Yes, all reputable ceiling t grid suppliers test to ASTM E119, EN 1365 (fire resistance) and EN 13964 for load/bending. Xingyuan products also meet French M1, Euroclass A1, and CE/SGS certifications.

Q5. What is the typical lifespan and maintenance need?

A: High-quality systems offer ≥30 years lifespan, with minimal routine inspection required. Antimicrobial-coated variants maintain surface hygiene, ideal for healthcare.

Q6. How is the "drywall ceiling grid price" quoted?

A: Prices depend on grid thickness, coating, and volume; typical ex-factory price in 2024: USD 1.60–2.20/m for standard galvanized, aluminum grids: USD 2.40+/m. Tile (600x600mm; gridstone) is typically USD 2.40–4.60/pc FOB.

Q7. What installation standards and tolerances should be followed?

A: Installers should adhere to EN 13964/ASTM C636 (tolerance for squareness: ±0.6mm/m; levelness: ±1.5mm over 10m span). Laser line guides and adjustable hangers are recommended for high-precision applications.

Delivery, Warranty, and After-Sales Support

Warranty: 10-year structural and anti-corrosion warranty; extended lifecycle support for healthcare, industrial, and public infrastructure projects.

Customer Service: ✓ 24h project technical support, BIM/3D layout design, sample delivery in 3–5 days, and ISO-traceable batch records for all outgoing shipments.

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025