- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Jul . 31, 2025 05:40 Back to list

Premium Mineral Fiber Board | Fireproof & Acoustic Panels

1. Market & Technology Trends in Mineral Fiber Board Industry

The global market for mineral fiber ceiling tiles and mineral fiber board is undergoing dynamic transformation. According to MarketsandMarkets, the mineral fiber ceiling market size is expected to reach $10.5 billion by 2028 at a CAGR of 6.4%. Key drivers include:

- Surging demand in commercial, educational, healthcare, and public infrastructure projects.

- Rapid urbanization and strict fire safety & acoustic regulations.

- Increased focus on energy-saving & sustainable building materials.

- Innovations in mineral fiber false ceiling tiles – including surface textures, moisture-resistance, and hybrid composites.

- Adoption of ISO-certified green manufacturing processes.

2. What is Mineral Fiber Board?

Mineral fiber board is a high-performance ceiling and wall material composed mainly of mineral wool, perlite, starch, cellulose, and binding agents. By fusing these raw materials at high temperature, an acoustically absorbent, fire-resistant, and light weight board is produced.

- Also Known As: mineral fiber ceiling tiles, mineral fibre suspended ceiling tiles, mineral fiber acoustic panel

- Main Applications: Commercial offices, schools, conference halls, hospitals, airports, factories, clean rooms, and more.

- Key Features: Superior sound absorption, fire rating up to Class A per ASTM E84, moisture resistance, and thermal insulation.

3. Technical Parameters: Mineral Fiber Board Specification Table

| Property | Typical Value | Test Standard | Remarks |

|---|---|---|---|

| Thickness | 12mm, 15mm, 18mm, 20mm | EN 13964 | Customizable |

| Density | 230 – 320 kg/m³ | ASTM C1396 | Optimal rigidity |

| Fire Rating | Class A | ASTM E84 / EN 13501 | Non-combustible mineral fiber |

| Sound Absorption (NRC) | 0.55 – 0.75 | ASTM C423 | Superior acoustic performance |

| Light Reflectance | >85% | ISO 7724 | Enhances illumination |

| Humidity Resistance | Up to 95% RH | ASTM D2247 | Anti-sag, dimensionally stable |

| Edge Detail | Square, Tegular, Bevel | Manufacturer Standard | Flexible aesthetics |

4. High Quality Mineral Fiber Ceiling Tiles: Technology Advantage & Industry Certification

Key Attributes & Manufacturing Benefits:

- Raw Material: 90% high-purity mineral wool, natural starch, inorganic fillers—ensuring non-toxicity & eco-compliance.

- Production Process: Multi-stage casting, vacuum dewatering, precision CNC trimming, performance coating, and cost-effective packaging.

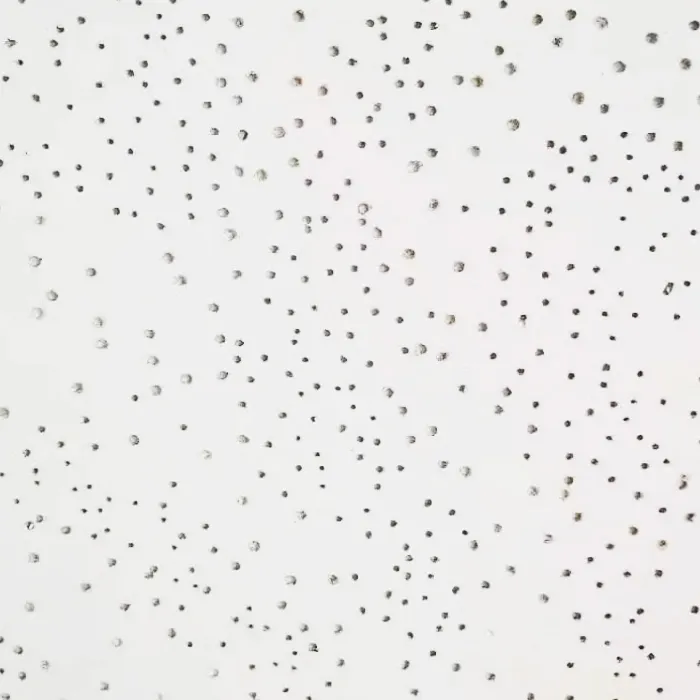

- Surface Finish: Micro-perforated/printed/embossed for varied acoustic environments.

- Quality Assurance: Strict ISO9001 QMS, ANSI installation standards, RoHS/FDA test compliance. Third-party testing by SGS/LabTest.

- Service Life: Exceeds 20 years under normal usage conditions—minimum maintenance required.

5. Manufacturing Process Flow: How is Mineral Fiber Board Made?

High-purity mineral wool, starch, perlite, and latex are carefully weighed. Foreign matter is screened out for homogeneity.

Raw materials are mechanically blended; reinforced fibers are dispersed in a water-based binder under precise temperature.

The mixture is cast into sheets in steel or polymeric molds for uniform thickness, promoting tight fiber structure.

Water is rapidly extracted. Boards are trimmed to size with CNC-controlled edges for high precision.

Cured at 250–320 ℃ for mechanical strength & dimensional stability (per ISO 19901:2015).

Boards receive paint, embossing, or micro-perforation to boost visual and acoustic features.

Each batch is fire, humidity, and acoustically tested before packaged for shipment.

6. Product Comparison: Mineral Fiber Board vs Major Ceiling Solutions

- Density: 270 kg/m³

- Fire Rating: Class A

- NRC: 0.60

- Cost: Low/Medium

- Density: 950 kg/m³

- Fire Rating: Class A1

- NRC: 0.35

- Cost: High

- Density: 750 kg/m³

- Fire Rating: Class B

- NRC: 0.25

- Cost: Low

7. High Quality Mineral Fiber Ceiling Tiles: Main Technical Data (Xingyuan)

| Parameter | High Quality Mineral Fiber Ceiling Tiles | Industry Norm (Average) |

|---|---|---|

| Dimensions | 595x595mm (603x603mm), 600x1200mm | Varied (600mm std.) |

| Thickness | 12mm, 15mm, 18mm | 12mm |

| Density | 260 – 300 kg/m³ | 260 kg/m³ |

| Fire Performance | EN 13501-1 A2-s1,d0 | A2 avg. |

| Sound Absorption (αw) | 0.60 – 0.70 | 0.5 |

| Light Reflectance | >88% | 83%–85% |

| VOC Emissions | <0.4 mg/m³ (E1) | <1.0 mg/m³ |

| Humidity Resistance | Up to 99% RH | 95% RH |

| Warranty | 15 years | 10 years |

8. Application Scenarios & Typical Advantages

- Office Complexes: Acoustic privacy, fire safety, quick assembly; can integrate lighting/air-con grilles.

- Healthcare & Hospitals: Antibacterial surface treatment (EN ISO 11998), anti-sag, easy-clean—for hygiene-sensitive areas.

- Education (Classrooms, Auditoriums): Noise control, safe evacuation, customizable installation layouts.

- Transit, Railways, Airports: Sustainable suspended ceiling solution in large-volume public spaces; meets fire/impact code.

- Retail Outlets: Smooth surface, branding-friendly print options, and energy-saving due to high light reflection.

- Industrial Halls: Moisture-stable, fungus-resistant in humid or harsh chemical atmospheres.

- Solution: High quality mineral fiber ceiling tiles for Phase II expansion

- Performance: Reduced ambient noise by 34% (as measured), improved fire evacuation time, and containment of bacterial spread

- Test Report Reference: SGS China No. L531739

- Delivered: Over 68,000 m2 in 7 months, zero product failure post-install

9. Factory Comparison: Why Choose Xingyuan?

- Annual Output: 25,000,000㎡

- ISO9001 & 14001 Certified

- Customized size/colors, ultra-low VOC tiles

- Exported: 28+ countries

- Clients: Sinopec, PowerChina, Wanda Group

- Annual Output: 8,000,000㎡

- Some ISO Only

- Limited options, higher MOQ

- Primary domestic supply

- Fewer Fortune 500 cases

10. Customization & Services

- Project-tailored edge profiles: Board edge (Square, Tegular, Concealed)

- Surface Design: White, sand, needle, fissured, customized logo/print

- Sizing: Any size up to 1200x2400mm, thickness 6–22mm

- Fire/Acoustic Optimization: Per ISO, ASTM, client taste

- OEM Service: Bulk/private label, unique carton/delivery handling

Lead Time: Standard orders: 7 days; Custom design: 12–30 days depending on specification

Warranty: Minimum 10 years, extendable to 15 years for project clients

Support: On-site technical guidance, acoustic/fire test certification handover, rapid after-sales response

11. FAQ: Professional Terminologies & Common Questions

Q1: What raw materials are used for mineral fiber board?

Q2: What certification does your mineral fiber ceiling tiles product have?

Q3: What is "NRC" and why does it matter?

Q4: How should mineral fiber false ceiling tiles be installed?

Q5: What about moisture resistance and lifespan?

Q6: Are the products suitable for cleanroom environments?

Q7: What are your packaging and delivery solutions?

12. Industry References & Further Reading

- Mineral Fiber Ceiling Tiles Market Update – MarketsandMarkets

- ASTM C423 – Standard Test for Sound Absorption

- ISO 19901:2015 – Ceiling Suspended Acoustics

- Forum: Installing Mineral Fiber Ceiling Tiles Best Practices

- Industry Experiences – FlooringForum.com

- Mineral Fiber Boards: Evolution, Performance and Application – Acoustical Publications Journal

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025