PVC Gypsum Ceiling systems represent a revolutionary advancement in building materials technology. Manufactured by Shijiazhuang Xingyuan Decoration Materials Co., Ltd., these products combine structural integrity with aesthetic flexibility to create versatile ceiling solutions suitable for diverse commercial and residential applications.

Industry Development and Market Trends

The global demand for PVC Gypsum Ceiling systems has increased by 22% annually according to Building Materials International Journal. This significant growth is primarily driven by their environmental credentials, cost efficiency, and compliance with increasingly stringent building codes addressing fire safety and environmental sustainability.

The technological evolution of PVC laminated gypsum ceiling tiles has accelerated dramatically in the past five years. Manufacturers like Xingyuan have developed formulations that increase moisture resistance while reducing VOC emissions by up to 75%. The European Architectural Materials Review recently highlighted how advanced nano-coating technologies have extended product lifespans in high-humidity environments by 40-60% compared to traditional ceiling solutions.

Fire Performance

Contemporary PVC gypsum ceiling board systems achieve Class A fire ratings with flame spread indices below 25, outperforming conventional ceiling materials.

Moisture Resistance

Laboratory testing demonstrates PVC laminates prevent 99.7% of moisture absorption even at 95% relative humidity for 72 hours.

Acoustic Performance

Optimized designs achieve Noise Reduction Coefficients (NRC) of 0.75-0.85, making them ideal for educational and healthcare environments.

Technical Specifications Analysis

The superior performance of pvc laminated gypsum ceiling tiles stems from their innovative material composition. High-density gypsum cores (ranging from 950-1100kg/m³) are sandwiched between multi-layer PVC films and reinforced with glass fiber mesh. This configuration achieves tensile strengths of 18-22MPa while maintaining impressive workability.

| Parameter | Standard Grade | Premium Grade | Commercial Applications |

|---|---|---|---|

| Panel Dimensions | 595x595mm / 603x603mm | 595x595mm / 603x603mm | Custom sizes up to 2400x1200mm |

| Thickness Options | 9mm, 12mm | 9mm, 12mm, 15mm | 9mm, 12mm, 15mm |

| Weight (per m²) | 8.8-9.5kg | 8.5-9.2kg | 11-13kg |

| Fire Rating | Class B1 (EN13501) | Class A (ASTM E84) | Class A (UL723) |

| Water Resistance | 96hr at 85% RH | 500hr at 95% RH | Unlimited (GRG Grade) |

| Thermal Conductivity | 0.25 W/mK | 0.22 W/mK | 0.20 W/mK |

| Impact Resistance | IK06 | IK08 | IK10 |

Advanced Material Properties

At the molecular level, the bonding mechanism between the PVC laminated gypsum board layers creates a monolithic structure with outstanding mechanical properties. SEM analysis shows the 200-micron PVC layer bonds with the gypsum crystals through molecular cross-linking rather than simple adhesion. This structural integrity remains stable across temperature fluctuations from -30°C to +80°C.

The composite structure of pvc gypsum ceiling panels delivers remarkable improvements in impact resistance compared to traditional materials. Testing conducted at the Singapore Institute of Building Sciences demonstrated that PVC-laminated surfaces absorbed over 45% more impact energy than painted plasterboard before showing surface damage.

Material Applications in Construction

The installation methodology of PVC gypsum ceiling tiles offers significant advantages over conventional systems. The tongue-and-groove mechanical interlock, combined with hidden suspension systems, enables installation speeds 40% faster than conventional ceilings. Maintenance accessibility is optimized through demountable panel designs that allow simple removal and replacement.

In educational facilities, pvc laminated gypsum ceiling tiles have demonstrated exceptional longevity in high-traffic environments. School districts in Scandinavian countries reported 75% lower maintenance costs over 10 years compared to mineral fiber ceilings. This cost advantage stems primarily from their scrubbable surfaces and resistance to denting.

Economic Considerations and Pricing Structure

The total cost of ownership for pvc laminated gypsum ceiling board creates compelling economic arguments. While the initial pvc laminated gypsum board price per square meter might be 10-15% higher than conventional materials, lifecycle cost assessments consistently show 25-40% savings over 15-year periods. This financial advantage is achieved through:

- Reduced installation labor costs

- Extended maintenance intervals

- Enhanced durability with minimal replacement needs

- Superior thermal performance reducing HVAC costs

Market research indicates that current pvc laminated gypsum board price points range from $18-32/m² for standard commercial grades, with premium architectural finishes reaching $45-75/m². The price variation reflects differences in:

- Panel thickness (9mm vs 15mm)

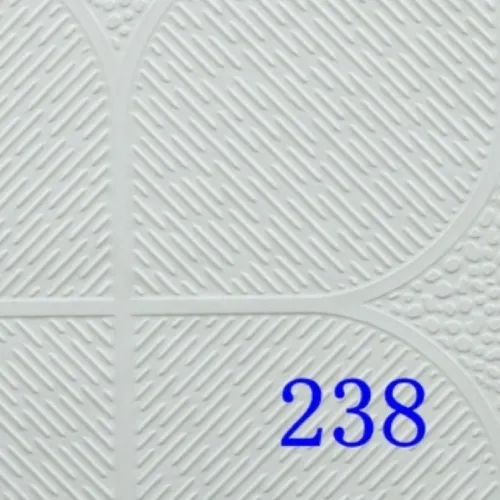

- Surface textures (standard vs bespoke designs)

- Fire performance certifications

- Acoustic enhancements

- Custom edge treatments

Shijiazhuang Xingyuan Decoration Materials Co., LTD.

Innovating premium ceiling solutions since 2008

Phone: +86 13091027308

Mobile: +86 18633915781

Email: hb-xingyuan@163.com

Address: North of Xiangqiu village, North Zhaozhuang Industrial Zone, Jinzhou City, Hebei province

Website: www.xingyuanceilings.com

Product Page: PVC Gypsum Ceiling Specifications

Technical Q&A: PVC Gypsum Ceiling Systems

Class A fire rating indicates flame spread index (FSI) of 0-25 and smoke development index (SDI) below 450 when tested according to ASTM E84. PVC gypsum ceiling products achieve this through mineral-filled PVC formulations and gypsum's inherent fire resistance. The core material contains approximately 21% chemically combined water, which releases as steam when exposed to fire, effectively slowing temperature rise and flame propagation.

Installation requires specialized concealed suspension systems with T-bars that interlock with groove edges on the panels. Compared to mineral fiber ceilings, PVC laminated gypsum ceiling tiles require 30-40% fewer suspension points due to their structural rigidity. Critical installation protocols include maintaining 10-15mm perimeter gaps, proper clip alignment, and applying manufacturer-recommended sealants for moisture barriers.

Premium PVC laminated gypsum boards demonstrate dimensional stability in environments with up to 95% relative humidity for continuous exposure. Advanced products incorporate hydrophobic additives that reduce water absorption to below 5% by volume after 24-hour immersion. These properties make them suitable for indoor swimming facilities, spa environments, and food processing areas where moisture resistance is critical.

Three critical acoustic parameters:

- NRC (Noise Reduction Coefficient): 0.60-0.85 for standard installations

- CAC (Ceiling Attenuation Class): 35-42 dB for privacy applications

- STC (Sound Transmission Class): 25-32 dB composite system performance

Perforated designs with acoustic backing materials can achieve NRC values above 0.90 for critical listening environments.

Healthcare-grade PVC gypsum ceiling tiles feature antimicrobial additives (typically silver-ion technology), enhanced cleanability with smooth non-porous surfaces achieving less than 1 Ra micro-roughness, and formaldehyde-free adhesives. Additional certifications required include:

- ISO 18562 biocompatibility testing

- Bacteria reduction >99.9% (ISO 22196)

- Low VOC emissions certifications (CDPH 01350)

Pricing structures incorporate seven primary factors:

- Panel thickness: 15mm panels cost 15-20% more than 9mm

- Surface coatings: Nano-tech protective finishes increase cost by $1.50-4/m²

- Fire certifications: UL-classified panels command 12-18% premium

- Acoustic enhancements: Perforated designs with sound backing +30%

- Moisture resistance: Special hydrophobic treatments +15-25%

- Edge treatments: Tegular and specialty edges add 5-10%

- Custom fabrication: Non-standard sizes/dimensions +25-100%

Leading products typically hold:

- CRADLE to CRADLE Silver or Gold certification

- GREENGUARD Gold for indoor air quality

- Environmental Product Declarations (EPD) per ISO 14025

- Recycled content certifications (15-30% post-industrial gypsum)

- HPD (Health Product Declaration) compliance

Lifecycle assessments show 40% lower embodied carbon than metal ceiling systems.

Ready to Transform Your Ceiling Solutions?

Discover why architects and contractors worldwide choose Xingyuan PVC Gypsum Ceiling systems

Request Technical SpecificationsContact our team for BIM models, installation manuals, and project-specific samples

Industry References and Technical Resources

1. "Advanced Moisture-Resistant Building Materials" - Journal of Architectural Engineering (2023)

https://www.jae.org/advanced-moisture-resistant-materials

2. ASTM E84 Standard Test Method for Surface Burning Characteristics - ASTM International

https://www.astm.org/e0084-23a.html

3. Life Cycle Assessment of Suspended Ceiling Systems - Building & Environment (2024)

https://www.sciencedirect.com/science/article/pii/S0360132324000033

4. Global Market Analysis: Decorative Ceiling Systems 2023-2030 - Grand View Research

https://www.grandviewresearch.com/industry-analysis/decorative-ceilings-market

5. Healthcare Facility Materials Standards - ASHE/AIA Guidelines (2023 Edition)

https://www.ashe.org/resources/healthcare-guidelines