- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

нов . 12, 2024 11:43 Back to list

rigid mineral wool insulation sheets

Rigid Mineral Wool Insulation Sheets A Comprehensive Overview

Rigid mineral wool insulation sheets are becoming increasingly popular in the construction and renovation industries due to their impressive thermal and acoustic insulation properties. This article delves into the benefits, applications, manufacturing process, and environmental impact of rigid mineral wool insulation sheets, providing a comprehensive overview for builders, architects, and homeowners alike.

What is Rigid Mineral Wool Insulation?

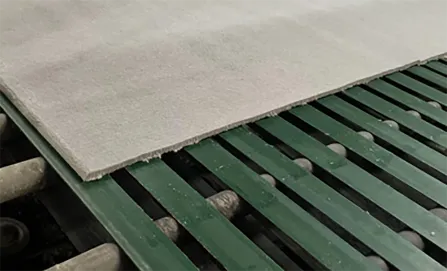

Rigid mineral wool, also known as stone wool or rock wool, is a type of insulation material created from natural or synthetic minerals. The production process involves melting rocks, such as basalt, and spinning them into fibers, which are then formed into rigid boards or sheets. The result is a dense, fire-resistant product that offers superior insulation performance.

Key Benefits

1. Thermal Performance Rigid mineral wool insulations have excellent thermal resistance properties, commonly represented by an R-value that indicates their ability to resist heat flow. This makes them an ideal choice for maintaining comfortable indoor temperatures while reducing energy costs.

2. Acoustic Insulation In addition to thermal insulation, mineral wool sheets are highly effective at absorbing sound. This quality makes them suitable for applications in residential buildings, offices, and commercial spaces, where noise reduction is paramount.

3. Fire Resistance One of the standout features of rigid mineral wool is its outstanding fire resistance. It can withstand high temperatures without melting or emitting toxic fumes, making it a safe choice for buildings that require adherence to strict fire safety regulations.

4. Moisture Resistance Rigid mineral wool does not absorb water, preventing mold growth and structural damage that can occur with less resilient insulation materials. This resistance is particularly valuable in environments with high humidity or fluctuating moisture levels.

5. Eco-Friendliness Many manufacturers produce rigid mineral wool insulation using recycled materials, aligning with the growing demand for sustainable building practices. Furthermore, the durability and energy efficiency of mineral wool can lead to reduced environmental impact over a building’s lifecycle.

rigid mineral wool insulation sheets

Applications

Rigid mineral wool insulation sheets are versatile and can be utilized in a variety of applications, including

- Roof Insulation They are often used in flat and pitched roofs, providing excellent thermal resistance while also protecting against noise and moisture infiltration. - Wall Insulation These sheets can be installed in both interior and exterior walls, enhancing energy efficiency and acoustic comfort in homes or commercial buildings. - Floor Insulation Rigid mineral wool can be used in ground floors or raised access floors to improve thermal performance and comfort levels. - Industrial Applications The insulation is widely used in industrial settings for pipes, vessels, and equipment that operate at high temperatures, given its fireproof capabilities.

Manufacturing Process

The manufacturing of rigid mineral wool insulation sheets generally follows these steps

1. Raw Material Preparation Natural rocks are crushed and combined with recyclable material such as glass or ceramics. 2. Melting The mixture is heated in a furnace to around 1,600°C, where it melts and turns into a molten mass. 3. Fiber Formation The molten rock is spun into fine fibers, creating a lightweight and porous structure. 4. Binding and Cutting The fibers are mixed with a binder, cured, and then cut into sheets of desired thickness and dimensions.

Environmental Impact

Choosing rigid mineral wool insulation is beneficial not just for individual buildings but also for the environment. Its energy efficiency contributes to lower greenhouse gas emissions during the operational lifespan of a building. Additionally, because it is produced from natural materials, the overall lifecycle impact of rigid mineral wool insulation is significantly lower compared to synthetic alternatives.

Conclusion

Rigid mineral wool insulation sheets offer a multitude of benefits that make them an excellent choice for a variety of construction projects. With their superb thermal and acoustic properties, fire resistance, moisture management, and eco-friendliness, these insulation materials are essential for building energy-efficient and comfortable environments. As regulatory standards for carbon emissions become stricter, the demand for high-performance insulation solutions like rigid mineral wool will likely continue to grow in the years to come.

-

Mineral Fiber Ceiling Tiles Embossed Surface PatternNewsAug.05,2025

-

Mineral Fiber Board Xingyuan Vision for Better SpacesNewsAug.05,2025

-

Drop Down Ceiling Tile Office Use FitNewsAug.05,2025

-

PVC Gypsum Ceiling White Base ColorNewsAug.05,2025

-

Access Panel on Ceiling Xingyuan Integrity EthicNewsAug.05,2025

-

Ceiling Trap Doors Fire Resistant DesignNewsAug.05,2025