- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Jul . 22, 2025 04:01 Back to list

Fire-Resistant Mineral Fiber Board & Acoustic Ceiling Tiles

The Future of Sustainable Acoustic Ceiling Solutions

The construction materials industry continues to evolve with sustainable solutions, and mineral fiber board has emerged as a leading product category. Offering exceptional acoustic control, thermal insulation, and fire resistance, these innovative materials are transforming commercial and institutional spaces globally. With technological advancements driving improved density ratios and surface treatments, the mineral fiber ceiling tiles market is projected to grow at 5.7% CAGR through 2028 according to Global Construction Insights.

About Shijiazhuang Xingyuan Decoration Materials

Shijiazhuang Xingyuan Decoration Materials Co., LTD. is a premier manufacturer of high-performance mineral fiber false ceiling tiles with state-of-the-art production facilities in Hebei province. Since 2010, we've provided innovative ceiling solutions to architects and contractors across 35 countries. Every mineral fiber board undergoes rigorous quality control to comply with international building standards including ASTM E84 Class A fire ratings and ISO 354 acoustic certifications.

Technical Specifications of Modern Mineral Fiber Board

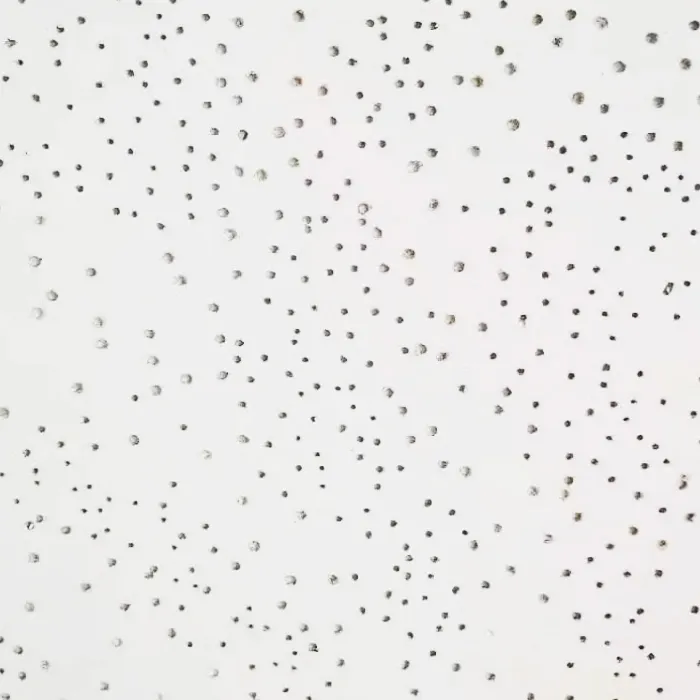

Contemporary mineral fibre suspended ceiling tiles have evolved significantly from earlier generations. Current materials consist primarily of mineral wool (70-85%) combined with starch binders (7-12%), latex modifiers (3-7%), and specialized additives to enhance performance attributes. The manufacturing process involves specialized fiberizing machines that create the distinctive porous structure essential for superior noise reduction.

| Parameter | Standard Value | Premium Range | Testing Standard |

|---|---|---|---|

| Noise Reduction Coefficient (NRC) | 0.50 - 0.65 | 0.70 - 0.95 | ASTM C423 |

| Fire Rating | Class A | Class A (ASTM E84) | UL 723 / ASTM E84 |

| Thermal Conductivity (λ) | 0.045 - 0.050 W/m·K | 0.038 - 0.042 W/m·K | ISO 8301 |

| Density | 280 - 350 kg/m³ | 350 - 450 kg/m³ | ASTM C167 |

| Compressive Strength | 110 kPa | 220 kPa | ASTM C165 |

| Light Reflectance | 82% | 88-92% | ASTM E1477 |

| Humidity Resistance | ≤3% Expansion | ≤0.8% Expansion | ASTM C209 |

Performance Analysis: Technical Trends in Mineral Fiber Board

Premium Product Showcase

Xingyuan Decoration Materials specializes in manufacturing customized High quality Mineral Fiber Ceiling Tiles with exceptional technical specifications. Our mineral fiber board is available in dimensions including 600x600mm, 603x603mm, 603x1212mm, 605x1215mm, and 610x1220mm. We provide thickness options ranging from 6mm to 20mm (standard sizes: 6mm, 9mm, 12mm, 15mm, 18mm, 20mm) with custom specifications available upon request.

Industrial Applications of Mineral Fiber Board

Mineral fibre suspended ceiling tiles provide critical functionality in demanding environments:

- Healthcare Facilities: Superior acoustic control in patient rooms with 0.80+ NRC ratings

- Educational Institutions: Enhanced speech intelligibility in classrooms (Ceiling Attenuation Class 35+ dB)

- Office Environments: Open-plan solutions meeting WELL Building Standard requirements

- Transportation Hubs: Durable Class A fire-rated systems for airports and stations

- Industrial Facilities: Moisture-resistant panels for manufacturing plants and cleanrooms

The unique properties of mineral fiber ceiling tiles contribute significantly to occupant well-being. According to the International WELL Building Institute, properly designed acoustic environments can improve cognitive function by 15-25% and reduce stress-related hormones by 20%. This makes mineral fiber board installations crucial elements in modern architectural design.

Mineral Fiber Board Technical FAQ

What distinguishes mineral fiber board from other ceiling materials?

Mineral fiber board combines superior sound absorption (NRC 0.70+) with exceptional fire resistance (Class A rating) due to its inorganic composition. Unlike gypsum or metal ceilings, it offers acoustic performance without requiring additional treatments. The unique fibrous structure creates energy-dissipating air pockets that effectively reduce noise transmission.

How does board thickness affect acoustic performance?

Thickness directly influences low-frequency sound absorption. 15mm mineral fiber ceiling tiles achieve 40% better 250Hz absorption than 9mm panels. The optimal thickness depends on room size and noise characteristics - larger spaces generally require thicker 15-20mm panels for balanced acoustics across all frequencies.

What are the critical ASTM standards for mineral fiber board?

Primary standards include: ASTM C423 (Sound Absorption), ASTM E84 (Surface Burning Characteristics), ASTM C209 (Physical Properties), and ASTM C167 (Density). Premium mineral fibre suspended ceiling tiles often exceed minimum requirements, particularly in humidity resistance testing where expansion should remain below 0.8% under ASTM C209 conditions.

How do environmental conditions affect mineral fiber performance?

Modern mineral fiber false ceiling tiles incorporate hydrophobic additives that limit moisture absorption to ≤1% even at 90% RH. Temperature cycling (-20°C to +60°C) causes minimal dimensional change (±0.07%) in quality products. However, condensation exposure should be avoided as prolonged wetting can degrade binders over time.

What are the installation requirements for suspended systems?

Proper installation requires ASTM C635-compliant grid systems with main tees spaced ≤1.2m apart. Perimeter gaps should allow 10-15mm expansion space. Heavy panels (>15kg/m²) need additional support clips at mid-span points. Our high-quality tiles feature reinforced edges to prevent sagging in standard 600x600mm configurations.

What sustainability certifications apply to mineral fiber products?

Premium mineral fiber board typically holds LEED MRc4 (Recycled Content) and MRc5 (Regional Materials) credits. Additional certifications include EPDs (Environmental Product Declarations) verifying 30-50% recycled content and GREENGUARD Gold for low VOC emissions. Our tiles contain 40% post-industrial mineral wool, contributing to circular economy principles.

How does surface treatment impact performance?

Micro-perforated finishes enhance high-frequency absorption by 15-20% while maintaining humidity resistance. Recent innovations include photocatalytic titanium dioxide coatings that actively reduce airborne pollutants. However, thick paint layers can reduce NRC by up to 0.15 points, so factory-applied finishes are recommended over field-painting.

Advanced Technology in Modern Manufacturing

The production of mineral fiber ceiling tiles has undergone significant technological transformation. Contemporary manufacturing plants utilize computer-controlled fiberizing systems that precisely regulate fiber diameter distribution for optimized acoustic performance. Advanced binder injection systems achieve uniform distribution while reducing VOC content to

Contact Information

Phone: +86 13091027308

Mobile: +86 18633915781

Email: hb-xingyuan@163.com

Factory Address

North of Xiangqiu village, North Zhaozhuang Industrial Zone, Jinzhou City, Hebei province

"Recent advances in mineral wool acoustics have fundamentally transformed the noise control capabilities of suspended ceiling systems. Modern formulations achieve NRC values exceeding 0.90 previously only possible with specialized acoustic panels." - Dr. Elena Rodriguez, Construction Materials Science Review (2023)

https://www.constr-materials-sci.com/advances-in-mineral-wool-acoustics

"The mineral fiber ceiling market is experiencing significant growth in the healthcare and education sectors, driven by enhanced acoustic standards in building codes globally. Innovation focus areas include humidity-resistant binders and recycled material integration." - Global Sustainable Building Materials Report, Building Technologies Institute (2024)

https://bti.org/global-sustainable-building-materials-report

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025