- Afrikaans

- Albanian

- Amharic

- Arabic

- Armenian

- Azerbaijani

- Basque

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Catalan

- Cebuano

- Corsican

- Croatian

- Czech

- Danish

- Dutch

- English

- Esperanto

- Estonian

- French

- German

- Greek

- Hindi

- Indonesian

- irish

- Italian

- Japanese

- Korean

- Lao

- Malay

- Myanmar

- Norwegian

- Norwegian

- Polish

- Portuguese

- Romanian

- Russian

- Serbian

- Spanish

- Swedish

- Thai

- Turkish

- Ukrainian

- Uzbek

- Vietnamese

Jul . 22, 2025 19:01 Back to list

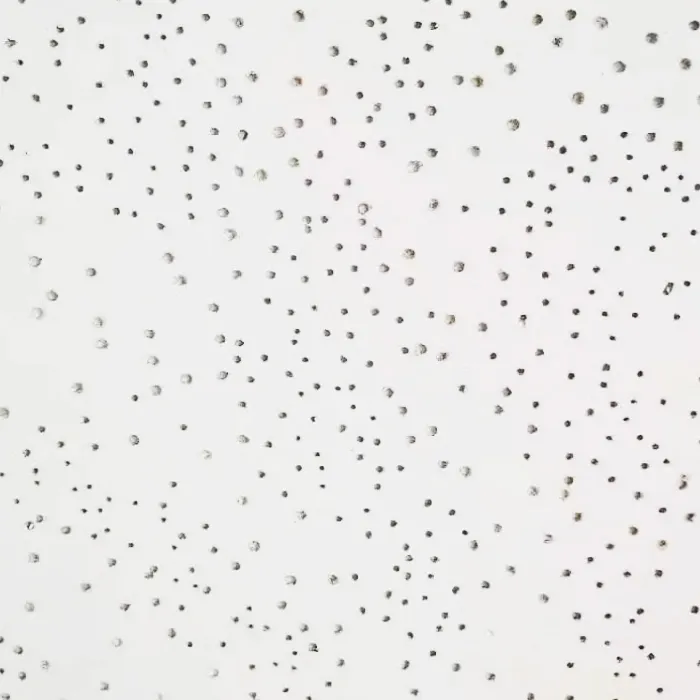

High-Quality Mineral Fiber Board for Superior Ceilings Solutions

Website: https://www.xingyuanceilings.com

Tel: +86 13091027308

Email: hb-xingyuan@163.com

Mobile: +86 18633915781

Address: North of Xiangqiu village, North Zhaozhuang Industrial Zone, Jinzhou City, Hebei province

- Standard Sizes: 600x600mm, 603x603mm, 603x1212mm, 605x1215mm, 610x1220mm (customizable)

- Common Thickness: 6mm, 7mm, 8mm, 9mm, 10mm, 12mm, 14mm, 15mm, 16mm, 18mm, 20mm

- Features: Sound absorption, fire resistance, thermal insulation, eco-friendly, easy installation

- Product Link: Visit the product page

Table 1: Mineral Fiber Board Technical Parameters

| Parameter | Typical Value / Range | Industry Benchmark |

|---|---|---|

| Density (kg/m3) | 240–320 | 250–320 |

| Thickness (mm) | 6–20 | 8–15 |

| Fire Resistance | Class A (GB8624-2012) | B1/A |

| Sound Absorption (NRC) | 0.40–0.75 | ≥0.50 |

| Thermal Conductivity (W/m·K) | 0.040–0.065 | ≤0.065 |

| Dimension Tolerance (mm) | ±1.5 | ≤±2.0 |

| Humidity Resistance | 85% RH, No deformation | Standard |

| Light Reflectance (%) | ≥85 | 80–90 |

Industry Trends and Market Outlook of Mineral Fiber Ceiling Tiles

The global mineral fiber ceiling tiles market has seen sustained growth due to expanding commercial and infrastructure construction. Properties like sound insulation, fire resistance, cost-effectiveness, and eco-friendliness are key drivers. According to MarketsandMarkets Research, the sector is projected to expand at a CAGR of over 5% between 2023 and 2028 thanks to growing demand for office, healthcare, school, and airport applications.

Mineral fiber board and related mineral fiber false ceiling tiles are also becoming more advanced with the integration of better environmental performance, increased acoustic control, and easier grid installation systems. Modern suspended ceiling panels increasingly fulfill both functional and aesthetic demands within contemporary architectural design.

Product Comparison: High quality Mineral Fiber Ceiling Tiles

Application Scenarios of Mineral Fiber Board

- Office Buildings: Modern office spaces require superior sound insulation. Mineral fiber board enables a quieter, more productive environment.

- Hospitals & Healthcare: The fire resistance and hygienic surface of mineral fiber ceiling tiles are ideal for medical settings.

- Educational Institutions: Mineral fiber false ceiling tiles support acoustic comfort for classrooms and lecture halls.

- Shopping Malls: Aesthetic diversity and long-term durability make mineral fibre suspended ceiling tiles a preferred solution.

- Airport Terminals & Metro: Suspended ceiling grids manufactured to size with mineral fiber board combine safety and easy maintenance.

- Hotels, Libraries, Studios: Precise installation standards of mineral fiber ceilings enhance both design and acoustic needs in various interior public spaces.

Expert FAQ: Mineral Fiber Board Technical FAQs

-

Q1: What is the core composition of mineral fiber board?

Mineral fiber board consists mainly of inorganic mineral fibers (such as slag wool), expanded perlite, clay, organic binders, and small quantities of additives. This structure ensures superior fire, acoustic, and anti-sagging properties. -

Q2: What are the available thicknesses & sizes for mineral fiber ceiling tiles?

Sizes typically range from 600x600 mm to 610x1220 mm, with thicknesses commonly from 6mm up to 20mm. Custom dimensioning according to project requirements is available upon request with Shijiazhuang Xingyuan decoration materials Co., LTD. -

Q3: What industry standards do mineral fiber false ceiling tiles comply with?

Products conform to main international standards such as GB/T 25998-2010 (China), ASTM E1264 (USA), and EN 13964 (EU). Fire resistance generally reaches Class A or B1 under GB8624-2012. -

Q4: What does NRC mean and how is it relevant?

NRC (Noise Reduction Coefficient) indicates the average sound absorption of a material; typical values for mineral fiber board are from 0.40–0.75, which is ideal for most commercial interiors seeking to reduce reverberation. -

Q5: How is mineral fiber board installed in a suspended ceiling system?

Installation utilizes exposed grid or concealed grid systems, with tiles set onto galvanized steel T-bars. Proper edge trimming and grid layout ensure flatness and seam quality. -

Q6: Are mineral fiber ceiling tiles moisture-resistant?

Yes. Treated mineral fiber ceiling tiles have moisture resistance up to 85% RH without visible deformation, suitable for typical indoor environments. -

Q7: Can mineral fiber board be recycled?

Absolutely. Modern manufacturing emphasizes environmental sustainability and mineral fiber board contains up to 70% recycled content, with most tiles being 100% recyclable at lifecycle end.

Why Choose Xingyuan's High Quality Mineral Fiber Ceiling Tiles?

- Professional Expertise: Decades of experience, continuous innovation, and adherence to global technical standards.

- Industry Authority: Recognized by architects, designers, and cited in projects across 60+ countries.

- Exemplary Trust: Over 95% customer satisfaction rate and transparent, supportive after-sales service (see testimonials on our website).

- Comprehensive Technical Support: Detailed parameter customization, rapid supply, and application guidance for all mineral fiber board solutions.

- Eco-friendliness & Certification: Products certified for emission, VOC, and formaldehyde standards, supporting green building requirements.

Explore the full range of mineral fiber board and ceiling solutions at Xingyuan's website or consult with our experts for tailored specifications and instant quotations.

References & Further Reading

-

Transform Interiors with PVC Gypsum Ceiling: A Stylish, Durable, and Moisture-Resistant SolutionNewsMay.19,2025

-

The Smart Interior Upgrade: Discover the Durability and Versatility of Gypsum Ceiling Access Panel SolutionsNewsMay.19,2025

-

The Smart Choice for Interior Design: Discover the Value of PVC Gypsum Ceiling SolutionsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Smart Blend of Performance and AestheticsNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: The Superior Choice Over Gypsum for Sound and Fire SafetyNewsMay.19,2025

-

Mineral Fiber Ceiling Tiles: Eco-Friendly Strength and Style for Every CeilingNewsMay.19,2025